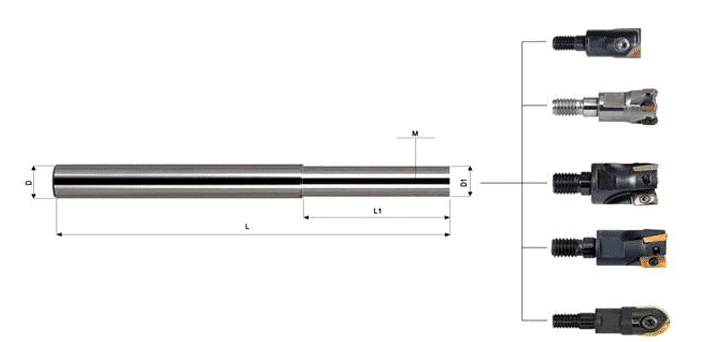

Cylindrical Solid Carbide Extension Shank With Thread

Solid Tungsten Carbide Extension Shank is widely used for screwed modular endmills and its anti-vibration property can effectively improve the lifetime of the screwed modular endmill and provide more accurate milling capability.

Sintering

HIP.

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder

Excellent.

Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

Thread

Conection

The carbide extension shank can be screwed onto changeable modular endmills and its anti-vibration property can provide longer tool life and extremely good surface?finish.

Standard Size

Code

OD

ID

Length

12-100-M6

12

M6

100

12-150-M6

12

M6

150

16-100-M8

16

M8

100

16-150-M8

16

M8

150

16-200-M8

16

M8

200

16-250-M8

16

M8

250

16-300-M8

16

M8

300

20-100-M10

20

M10

100

20-150-M10

20

M10

150

20-200-M10

20

M10

200

20-250-M10

20

M10

250

20-300-M10

20

M10

300

25-150-M12

25

M12

150

25-200-M12

25

M12

200

25-250-M12

25

M12

250

25-300-M12

25

M12

300

32-150-M16

32

M16

150

32-200-M16

32

M16

200

32-250-M16

32

M16

250

32-300-M16

32

M16

300

32-350-M16

32

M16

350

32-400-M16

32

M16

400

OEM Custom Service

We can develop grades as per your requirement and make the same shape as your drawing. Laser marking and neutral package are also available for your benefits.

Grade

grade

? MT20.8

ISO range

? K40-K50

WC+other carbide

%

85

Co

%

15

WC grain size

μm

0.8

density

g/㎝3

13.95

hardness

Hv30

1350

HRA

? 89.5

transverse rupture strength

N/mm2

3800

kpsi

? 551

fracture toughness

Mpa.m?

17.5

young’s modulus

kpsi

79086

compressive strength

kpsi

957

Coolant Tungsten Carbide Rods with oil duct

Both carbide rod with straight coolant holes and helical coolant holes are supplied. Different grades are also available in stock. The internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities. It is widely used in deep-hole drills and thread end mills.

Type

D(mm)

d(mm)

Deviation of holes

position≤(mm)

L(mm)

D

Tol.

d

Tol.

L

Tol.

OD4.0×ID1.0×330

4.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD5.0×ID1.0×330

5.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD5.0×ID1.5×330

5.0

+0.2/+0.6

1.5

±0.15

0.2

330

0/+5

OD6.0×ID1.0×330

6.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD6.0×ID1.5×330

6.0

+0.2/+0.6

1.5

±0.15

0.2

330

0/+5

OD8.0×ID1.0×330

8.0

+0.2/+0.6

1.0

±0.15

0.25

330

0/+5

OD8.0×ID1.5×330

8.0

+0.2/+0.6

1.5

±0.15

0.25

330

0/+5

OD9.0×ID1.0×330

9.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD10.0×ID1.0×330

10.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD10.0×ID2.0×330

10.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD11.0×ID1.0×330

11.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD12.0×ID1.0×330

12.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD12.0×ID2.0×330

12.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD14.0×ID2.0×330

14.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD16.0×ID2.0×330

16.0

+0.4/+0.8

2.0

±0.2

0.25

330

0/+5

OD16.0×ID3.0×330

16.0

+0.4/+0.8

3.0

±0.25

0.25

330

0/+5

OD18.0×ID3.0×330

18.0

+0.4/+0.8

3.0

±0.25

0.3

330

0/+5

OD20.0×ID3.0×330

20.0

+0.4/+0.8

3.0

±0.25

0.3

330

0/+5

20.0≤Dia≤40.0 are available on request

20.0≤Dia≤40.0 are available on request

Type

D(mm)

TK(mm)

d(mm)

Deviation of holes position≤(mm)

L(mm)

D

Tol.(mm)

TK

Tol.

d

Tol.(mm)

L

Tol.(mm)

OD4.3×2ID0.8×1.8×330

4.3

0/+0.6

1.8

-0.4/0

0.8

±0.10

0.15

330

0/+10

OD5.3×2ID0.8×2.0×330

5.3

0/+0.6

2.0

-0.4/0

0.8

±0.10

0.20

330

0/+10

OD6.3×2ID1.0×3.0×330

6.3

0/+0.6

3.0

-0.5/0

1.0

±0.15

0.20

330

0/+10

OD7.3×2ID1.0×3.5×330

7.3

0/+0.6

3.5

-0.5/0

1.0

±0.15

0.20

330

0/+10

OD8.3×2ID1.0×4.0×330

8.3

0/+0.6

4.0

-0.6/0

1.0

±0.15

0.20

330

0/+10

OD9.3×2ID1.4×4.0×330

9.3

0/+0.6

4.0

-0.6/0

1.4

±0.15

0.20

330

0/+10

OD10.3×2ID1.4×5.0×330

10.3

0/+0.6

5.0

-0.6/0

1.4

±0.15

0.20

330

0/+10

OD11.3×2ID1.4×5.0×330

11.3

0/+0.6

5.0

-0.6/0

1.4

±0.15

0.28

330

0/+10

OD12.3×2ID1.75×6.0×330

12.3

0/+0.6

6.0

-0.6/0

1.75

±0.15

0.30

330

0/+10

OD13.3×2ID1.75×6.0×330

13.3

0/+0.6

6.0

-0.6/0

1.75

±0.15

0.34

330

0/+10

OD14.3×2ID1.75×7.0×330

14.3

0/+0.6

7.0

-0.6/0

1.75

±0.15

0.37

330

0/+10

OD15.3×2ID2.0×7.0×330

15.3

0/+0.6

7.0

-0.6/0

2.0

±0.20

0.37

330

0/+10

OD16.3×2ID2.0×8.0×330

16.3

0/+0.6

8.0

-0.6/0

2.0

±0.20

0.40

330

0/+10

OD17.3×2ID2.0×8.0×330

17.3

0/+0.8

8.0

-0.6/0

2.0

±0.20

0.47

330

0/+10

OD18.3×2ID2.0×9.0×330

18.3

0/+0.8

9.0

-0.6/0

2.0

±0.20

0.50

330

0/+10

OD19.3×2ID2.0×9.0×330

19.3

0/+0.8

9.0

-0.6/0

2.0

±0.20

0.50

330

0/+10

OD20.3×2ID2.5×10.0×330

20.3

0/+0.8

10.0

-0.8/0

2.5

±0.25

0.50

330

0/+10

Type

D(mm)

d(mm)

Tk

a

Pitch

D

Tolerance

d

Tolerance

TK

Tolerance

P1

P2

P3

Tolerance

OD3.3×2ID0.4×1.7×330

3.3

2.33

0.4

±0.10

1.7

0/-0.3

≤0.08

15.89

16.32

16.77

±0.23

OD4.3×2ID0.6×2.2×330

4.3

2.33

0.6

±0.15

2.2

0/-0.3

≤0.10

21.19

21.77

22.36

±0.31

OD5.3×2ID0.7×2.6×330

5.3

2.67

0.7

±0.15

2.6

0/-0.4

≤0.13

26.49

27.21

27.95

±0.38

OD6.3×2ID0.7×2.6×330

6.3

2.5

0.7

±0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD6.3×2ID1.0×2.6×330

6.3

2.5

1.0

±0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD7.3×2ID1.0×3.7×330

7.3

2.5

1.0

±0.15

3.7

0/-0.4

≤0.15

37.09

38.09

39.13

±0.54

OD8.3×2ID1.0×4.0×330

8.3

2.5

1.0

±0.15

4.0

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD8.3×2ID1.0×3.5×330

8.3

2.5

1.0

±0.15

3.5

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD8.3×2ID0.6×2.8×330

8.3

2.5

0.6

±0.15

2.8

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD9.3×2ID1.4×4.8×330

9.3

2.5

1.4

±0.15

4.8

0/-0.6

≤0.20

47.68

48.97

50.32

±0.69

OD10.3×2ID1.4×4.8×330

10.3

2.75

1.4

±0.15

4.8

0/-0.6

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID0.7×2.6×330

10.3

2.75

0.7

±0.15

2.6

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID1.0×3.0×330

10.3

2.75

1.0

±0.15

3.0

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID1.4×5.0×330

10.3

2.75

1.4

±0.15

5.0

0/-0.6

≤0.20

52.98

54.41

55.91

±0.77

OD11.3×2ID1.4×5.3×330

11.3

2.75

1.4

±0.15

5.3

0/-0.8

≤0.28

58.28

59.86

61.5

±0.85

OD12.3×2ID1.4×6.25×330

12.3

2.75

1.4

±0.15

6.25

0/-0.8

≤0.30

63.58

65.3

67.09

±0.92

OD12.3×2ID1.75×6.0×330

12.3

2.75

1.75

±0.20

6.0

0/-0.8

≤0.30

63.58

65.3

67.09

±0.92

OD13.3×2ID1.75×6.5×330

13.3

3.0

1.75

±0.20

6.5

0/-0.8

≤0.34

68.87

70.74

72.68

±1.00

OD14.3×2ID1.75×7.1×330

14.3

3.5

1.75

±0.20

7.1

0/-0.8

≤0.37

74.17

76.18

78.27

±1.08

OD14.3×2ID0.8×3.5×330

14.3

3.5

0.8

±0.15

3.5

0/-0.4

≤0.37

74.17

76.18

78.27

±1.08

OD14.3×2ID1.4×4.5×330

14.3

3.5

1.4

±0.15

4.5

0/-0.6

≤0.37

74.17

76.18

78.27

±1.08

OD15.3×2ID1.75×7.7×330

15.3

3.5

1.75

±0.20

7.7

0/-0.8

≤0.40

79.47

81.62

83.86

±1.15

OD16.3×2ID1.75×8.3×330

16.3

3.5

1.75

±0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

±1.23

OD16.3×2ID2.0×8.0×330

16.3

3.5

2.0

±0.20

8.0

0/-0.6

≤0.40

84.77

87.06

89.45

±1.23

OD17.3×2ID1.75×8.9×330

17.3

3.5

1.75

±0.20

8.9

0/-0.8

≤0.47

90.07

92.5

95.04

±1.31

OD18.3×2ID2.0×9.55×330

18.3

3.5

2.0

±0.25

9.55

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD18.3×2ID1.75×9.15×330

18.3

3.5

1.75

±0.20

9.15

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD19.3×2ID2.0×10×330

19.3

3.5

2.0

±0.25

10.0

0/-0.8

≤0.50

100.66

103.39

106.22

±1.46

OD20.3×2ID2.0×10.4×330

20.3

3.5

2.0

±0.25

10.4

0/-1

≤0.50

105.96

108.83

111.81

±1.54

Note: D<18.3, L>100, L Tolerance0~+7; L<100, L Tolerance0~+5.? D ≥ 18.3, L Tolerance+3~+10.

Note: D<18.3, L>100, L Tolerance0~+7, L<100, L Tolerance0~+5, D≥18.3, Length Tolerance+3~+10

Type

D(mm)

d(mm)

TK(mm)

a

Ptich

D

Tol.

d

Tol.

TK

Tol.

P 1

P 2

P 3

Tol.

OD6.3×2ID0.6×1.9×LC

6.3

2.5

0.6

±0.15

1.9

0/-0.4

≤0.15

18.20

18.85

19.52

±0.34

OD6.3×2ID0.5×2.2×LC

6.3

2.5

0.5

±0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

±0.42

OD8.3×2ID0.65×2.7×LC

8.3

2.5

0.65

±0.15

2.7

0/-0.6

≤0.15

28.91

29.95

31.04

±0.56

OD10.3×2ID0.8×3.5×LC

10.3

2.75

0.8

±0.15

3.5

0/-0.8

≤0.20

36.14

37.44

38.8

±0.70

OD12.3×2ID0.9×4.2×LC

12.3

2.75

0.9

±0.15

4.2

0/-0.8

≤0.30

43.37

44.93

46.55

±0.84

OD14.3×2ID1.0×4.7×LC

14.3

3.5

1.0

±0.20

4.7

0/-0.8

≤0.37

50.6

52.42

54.31

±0.98

OD16.3×2ID1.2×5.5×LC

16.3

3.5

1.2

±0.20

5.5

0/-0.8

≤0.40

57.82

59.9

62.07

±1.12

OD18.3×2ID1.4×6.3×LC

18.3

3.5

1.4

±0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

±1.26

OD20.3×2ID1.5×7.1×LC

20.3

3.5

1.5

±0.20

7.1

0/-1.0

≤0.50

72.28

74.88

77.59

±1.40

Note: D<18.3, L>100, L Tolerance0~+7; L<100, L Tolerance0~+5. D≥18.3, L Tolerance+3~+10.

Type

D(mm)

d(mm)

TK

a

Pitch

D

Tol.

d

Tol.

TK

Tol.

P 1

P 2

P 3

Tol.

OD6.3×3ID0.5×2.9×LB

6.3

2.5

0.5

±0.15

2.9

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD8.3×3ID0.7×4.0×LB

8.3

2.5

0.7

±0.15

4

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD9.3×3ID0.7×4.0×LB

9.3

2.5

0.85

±0.15

5.1

0/-0.5

≤0.20

47.68

48.97

50.32

±0.69

OD10.3×3ID0.85×5.1×LB

10.3

2.75

0.85

±0.15

5.1

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

BФ12.3×3Ф1.1×6.3×LB

12.3

2.75

1.1

±0.15

6.3

0/-0.6

≤0.30

63.58

65.3

67.09

±0.92

OD14.3×3ID1.4×7.3×LB

14.3

3.5

1.4

±0.20

7.3

0/-0.8

≤0.40

74.17

76.18

78.27

±1.08

OD15.3×3ID1.4×7.3×LB

15.3

3.5

1.4

±0.20

7.8

0/-0.8

≤0.40

79.47

81.62

83.86

±1.15

OD16.3×3ID1.6×8.3×LB

16.3

3.5

1.6

±0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

±1.23

OD18.3×3ID1.7×9.5×LB

18.3

3.5

1.7

±0.20

9.5

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD20.3×3ID1.9×10.2×LB

20.3

3.5

1.9

±0.25

10.2

0/-0.8

≤0.50

105.96

108.83

111.81

±1.54

Note:? D<18.3, L>100, L Tolerance0~+7, L<100, L Tolerance0~+5, D≥18.3, Length Tolerance+3~+10

Type

D(mm)

d(mm)

Tk

a

Pitch

D

Tol.

d

Tolerance

TK

Tol.

P1

P2

P3

Tol.

OD6.3×3ID0.5×2.9×LB

6.3

2.5

0.5

±0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

±0.42

OD8.3×3ID0.7×4.0×LB

8.3

2.5

0.65

±0.15

2.7

0/-0.4

≤0.15

28.91

29.95

31.04

±0.56

OD10.3×3ID0.85×5.1×LB

10.3

2.75

0.8

±0.15

3.5

0/-0.4

≤0.20

36.14

37.44

38.8

±0.70

BФ12.3×3Ф1.1×6.3×LB

12.3

2.75

0.9

±0.15

4.2

0/-0.6

≤0.30

43.37

44.93

46.55

±0.84

OD14.3×3ID1.4×7.3×LB

14.3

3.5

1.0

±0.20

4.7

0/-0.6

≤0.37

50.60

52.42

54.31

±0.98

OD16.3×3ID1.6×8.3×LB

16.3

3.5

1.2

±0.20

5.5

0/-0.8

≤0.40

57.82

59.90

62.07

±1.12

OD18.3×3ID1.7×9.5×LB

18.3

3.5

1.4

±0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

±1.26

OD20.3×3ID1.9×10.2×LB

20.3

3.5

1.5

±0.20

7.1

0/-0.8

≤0.50

72.28

74.88

77.59

±1.40

Sintering

HIP.

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder

Excellent.

Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

Cooling

Internal.

The internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities. We supply not only straight coolant but also spiral coolant carbide rod.

OEM Custom Service

We can develop grades as per your requirement and make the same shape as your drawing. Laser marking and neutral package are also available for your benefits.

Grade

| grade | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO range | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC+other carbide | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC grain size | μm | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| density | g/㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| hardness | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| transverse rupture strength | N/mm2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| fracture toughness | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| young’s modulus | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| compressive strength | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

Grade | Properties and applications |

MT09U? | Ultra-fine grain WC with 9%Co Very high wear resistance and excellent deformation resistance High cutting speed milling, finishing For use on hardened steel, plastics, fibre reinforced materials, HRC55-65 |

MT10S? | Ultra-fine grain WC with 10%Co? Very high wear resistance and excellent deformation resistance High cutting speed milling&drilling For general usage and suitable for all kinds of material belowHRC45 |

MT12S? | Submicron grain WC with 12%Co High toughness and wear resistance Specially designed for machining stainless steel For use on stainless steel, nickel-based alloys, titanium alloy and special alloy |

MT25S? | Ultra-fine grain WC with 12%Co Very high toughness and high wear resistance Suitable for finishing processing and roughing of steels with hardness between 45 and 55HRC steels for surface treatments, nickel and nickel alloys |

MT06U? | Submicron grain WC with 6% Co Very high wear resistance High cutting speed For drilling and milling of plastic composites, PCB, ceramics, woods and MDF |

MT20.8? | Submicron grain WC with 15%Co High strength and toughness High-speed punching For use on solid carbide punches |

Solid Unground Tungsten Carbide Rod Blanks

Sintering

HIP.

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder

Excellent.

Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

Lead time

Fast.

Three different compaction methods, including extrusion, automatic press, and cold isostatic press are used for the maximum efficiency of carbide rod manufacturing.

Standard 330mm Length, Metric, Unit Milimeter

|

Diameter |

Tolerance |

Tolerance of Length |

Diameter |

Tolerance |

Tolerance of Length |

Diameter |

Tolerance |

Tolerance of Length |

|

0.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

9.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

19.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

|

1.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

10.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

20.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

|

1.2 |

+0.20/+0.45 |

‐0.0/+10.0 |

10.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

20.5 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

1.6 |

+0.20/+0.45 |

‐0.0/+10.0 |

11.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

21.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

1.8 |

+0.20/+0.45 |

‐0.0/+10.0 |

11.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

22.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

2.3 |

+0.20/+0.45 |

‐0.0/+10.0 |

12.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

23.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

2.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

12.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

24.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

3.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

13.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

25.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

3.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

13.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

26.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

4.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

14.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

27.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

4.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

14.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

28.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

5.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

15.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

29.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

5.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

15.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

30.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

6.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

16.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

31.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

6.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

16.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

32.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

7.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

17.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

33.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

7.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

17.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

34.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

8.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

18.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

35.0 |

+0.20/+0.80 |

‐0.0/+10.0 |

|

8.5 |

+0.20/+0.45 |

‐0.0/+10.0 |

18.5 |

+0.20/+0.60 |

‐0.0/+10.0 |

|||

|

9.0 |

+0.20/+0.45 |

‐0.0/+10.0 |

19.0 |

+0.20/+0.60 |

‐0.0/+10.0 |

Minimum Diameter? 0.3mm and Maximum Diameter 40mm

OEM Custom Service

We can develop grades as per your requirement and make the same shape as your drawing. Laser marking and neutral package are also available for your benefits.

Grade

| grade | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO range | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC+other carbide | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC grain size | μm | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| density | g/㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| hardness | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| transverse rupture strength | N/mm2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| fracture toughness | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| young’s modulus | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| compressive strength | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

Grade | Properties and applications |

MT09U? | Ultra-fine grain WC with 9%Co Very high wear resistance and excellent deformation resistance High cutting speed milling, finishing For use on hardened steel, plastics, fibre reinforced materials, HRC55-65 |

MT10S? | Ultra-fine grain WC with 10%Co? Very high wear resistance and excellent deformation resistance High cutting speed milling&drilling For general usage and suitable for all kinds of material belowHRC45 |

MT12S? | Submicron grain WC with 12%Co High toughness and wear resistance Specially designed for machining stainless steel For use on stainless steel, nickel-based alloys, titanium alloy and special alloy |

MT25S? | Ultra-fine grain WC with 12%Co Very high toughness and high wear resistance Suitable for finishing processing and roughing of steels with hardness between 45 and 55HRC steels for surface treatments, nickel and nickel alloys |

MT06U? | Submicron grain WC with 6% Co Very high wear resistance High cutting speed For drilling and milling of plastic composites, PCB, ceramics, woods and MDF |

MT20.8? | Submicron grain WC with 15%Co High strength and toughness High-speed punching For use on solid carbide punches |

Cut-to-Length (CTL) Tungsten Carbide Rod, Ground, Polished, Chamfer one end

We have one of the largest and most complete lines of ground CTL carbide rods for cutting tool blanks in stock. Meetyou Carbide proudly announces that we have achieved the best cost-effectiveness for this kind of rods for cutting tool blanks. Because we use a unique method of pressing technology combined with the supreme quality powder from Germany H.C.Starck.

h6

Polished.

Our standard tolerance for the diameter is h6 polished. We can also provide h5 polished or other tolerance as per your requirement.

Length

Cut.

Both advanced wire cutting and diamond wheel cutting are applied to cut the carbide rod into the length you need.

One End

Chamfered

45 degree chamfered one end is provided for better looking and a smooth edge.

- Complete lines of ground cut to length carbide rod for cutting tool blanks

- Standard h6 ISO diameter tolerances in inch and metric lengths and diameters

- Special perform like male center, female center, ball nose, step reduction, and shaped points, etc are available according to your drawing

Standard Size ,Metric, Milimeter

|

Φ3.0 X 60 |

Φ8.0 X 50 |

Φ12.0 X 120 |

|

Φ4.0 X 40 |

Φ8.0 X 60 |

Φ13.0 X 100 |

|

Φ4.0 X 46 |

Φ8.0 X 63 |

Φ14.0 X 75 |

|

Φ4.0 X 50 |

Φ8.0 X 75 |

Φ14.0 X 80 |

|

Φ4.0 X 60 |

Φ8.0 X 90 |

Φ14.0 X 83 |

|

Φ4.0 X 75 |

Φ8.0 X 100 |

Φ14.0 X 100 |

|

Φ4.0 X 100 |

Φ10.0 X 50 |

Φ16.0 X 80 |

|

Φ5.0 X 50 |

Φ10.0 X 70 |

Φ16.0 X 90 |

|

Φ5.0 X 60 |

Φ10.0 X 72 |

Φ20.0 X 100 |

|

Φ5.0 X 100 |

Φ10.0 X 75 |

|

|

Φ6.0 X 40 |

Φ10.0 X 80 |

|

|

Φ6.0 X 50 |

Φ10.0 X 90 |

|

|

Φ6.0 X 58 |

Φ10.0 X 100 |

|

|

Φ6.0 X 60 |

Φ12.0 X 70 |

|

|

Φ6.0 X 67 |

Φ12.0 X 79 |

|

|

Φ6.0 X 75 |

Φ12.0 X 83 |

|

|

Φ6.0 X 100 |

Φ12.0 X 100 |

OEM Custom Service

We can develop grades as per your requirement and make the same shape as your drawing. Laser marking and neutral package are also available for your benefits.

Grade

| grade | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ISO range | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC+other carbide | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| WC grain size | μm | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| density | g/㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| hardness | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| transverse rupture strength | N/mm2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| fracture toughness | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| young’s modulus | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| compressive strength | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

Grade | Properties and applications |

MT09U? | Ultra-fine grain WC with 9%Co Very high wear resistance and excellent deformation resistance High cutting speed milling, finishing For use on hardened steel, plastics, fibre reinforced materials, HRC55-65 |

MT10S? | Ultra-fine grain WC with 10%Co? Very high wear resistance and excellent deformation resistance High cutting speed milling&drilling For general usage and suitable for all kinds of material belowHRC45 |

MT12S? | Submicron grain WC with 12%Co High toughness and wear resistance Specially designed for machining stainless steel For use on stainless steel, nickel-based alloys, titanium alloy and special alloy |

MT25S? | Ultra-fine grain WC with 12%Co Very high toughness and high wear resistance Suitable for finishing processing and roughing of steels with hardness between 45 and 55HRC steels for surface treatments, nickel and nickel alloys |

MT06U? | Submicron grain WC with 6% Co Very high wear resistance High cutting speed For drilling and milling of plastic composites, PCB, ceramics, woods and MDF |

MT20.8? | Submicron grain WC with 15%Co High strength and toughness High-speed punching For use on solid carbide punches |