Carbides are composed of refractory carbides with high compressive strength, hardness, and elastic modulus, which are difficult to plastically deform during the pressing process. To improve the formability of the powder and increase the strength of the compact, a binder must be added to the powder material before shaping.

As an intermediate auxiliary material, the binder must be completely removed during the degumming stage, as any residue can pose a quality risk to the product. The total carbon content in the alloy must be strictly controlled to produce high-quality carbide products. Although many factors can affect the total carbon content in carbide products, the application of the binder is a crucial aspect, especially when the quality of the tungsten carbide raw material is stable.

Therefore, the performance of the binder is a key factor directly affecting the properties of the blank and the final sintered product.

Research Status and Issues

Current Usage

According to surveys, some w?glik manufacturers have used synthetic resins, dextrin, starch, methyl alcohol, and cellulose as binders in the past. For example, East Germany used a mixture of ceresin, paraffin wax, and mineral oil with an addition rate of 48%-59%; General Electric in the United States used starch, rubber, and synthetic resins; the United Kingdom applied water-soluble fibers and polyacrylamide; and some manufacturers even added surfactants.

Foreign carbide manufacturers, equipped with advanced production equipment and high automation levels, use pipeline conveying for mixed material preparation equipment, fully automatic high-precision presses, and multi-atmosphere pressure degumming and sintering integrated furnaces. The binders used in foreign carbide production are primarily paraffin and PEG, with paraffin acetone as the ball milling medium, and rubber as a binder is very rare.

Currently, the widely used binders in domestic carbide manufacturers are rubber, paraffin, and polyethylene glycol (PEG). Depending on the foreign manufacturer from which the technology was introduced and the time of introduction, each manufacturers usage may vary. Manufacturers that have introduced Sandvik technology generally use PEG as a binder and adopt a spray drying process. Some use paraffin as a binder and also adopt a spray drying process. Some enterprises use a combination of binders, and there are also mixtures of rubber and paraffin. SMEs basically use the rubber process, with each type of binder having its own advantages and disadvantages.

Rubber Binders

In the late 1950s and early 1960s, the carbide industry in China used butadiene sodium rubber imported from the Soviet Union, which had stable rubber quality. Later, due to changes in the situation, domestically produced synthetic butadiene sodium rubber from Lanzhou was used. Due to manufacturing process technology and equipment issues, the quality stability of the rubber was poor. The butadiene sodium rubber dissolved in gasoline had a high gel content, and the solution was suspended, making filtration difficult, with high ash and impurity content, which affected the normal production of the alloy.

Rubber solvents have good formability and can press out products with complex shapes and larger volumes, and the compact is less likely to crack. However, the disadvantages include high ash content, high residual carbon, difficulty in precise carbon control, vacuum removal, and unstable product quality, and it is not suitable for the spray drying process.

Paraffin-Type Binders

Paraffin is derived from petroleum refining and is a mixture of various hydrocarbons, with a small amount of liquid “impurities” present as oil, and the solid component is saturated alkanes. The properties of paraffin are ultimately determined by its chemical composition, whether they are straight-chain, branched, or cyclic structures. Paraffins can be classified into: paraffin, microcrystalline wax, montan wax, vegetable wax, animal wax, and synthetic wax. There are dozens to hundreds of different varieties, each with different molecular weight, structure, performance, and uses.

The paraffin used for carbides is mainly composed of normal alkanes, with few straight-chain molecules and aromatic hydrocarbons. The molecular weight range is 360-540, with a melting point of 42-70 degrees and slight solubility in ethanol. Microcrystalline wax has a molecular weight of 580-700, mostly branched molecules, with more cyclic hydrocarbon compounds. Paraffin is brittle, while microcrystalline wax is stronger and more flexible, with higher tensile strength and melting point, greater adhesiveness, and is a saturated straight-chain hydrocarbon that can completely volatilize at high temperatures without leaving any residue and is easily removed under vacuum. This reduces the difficulty in controlling the carbon content and improves the precision of the carbon content in the alloy, but it has a low viscosity, resulting in low compaction strength and large elastic after-effect, which makes it prone to cracking at stress concentration areas, difficult to produce complex-shaped products, and the compacts are brittle and prone to chipping.

Water-Soluble Polymer Binders

PEG (Polyethylene Glycol) is a water-soluble polymer, and foreign literature classifies PEG as a synthetic wax. It is prepared by stepwise addition of ethylene oxide to water or ethylene glycol, with a molecular weight range of 200-20000. PEG is completely soluble in water and has very low solubility in ethanol at room temperature (less than 1%). It is compatible with many substances and shows the greatest compatibility with substances with high polarity. It is non-toxic and non-irritating. The formability of PEG is equivalent to that of paraffin, and it has less residual carbon. Therefore, it can be considered a safe and environmentally friendly binder suitable for spray drying. However, PEG has a serious tendency to absorb moisture, and its moisture absorption capacity decreases with increasing molecular weight. It has very strict requirements for humidity and temperature in the working environment. After absorbing moisture, the powder becomes hard, the pressing pressure increases, and higher requirements are placed on the press. Additionally, it is more difficult to form some complex products.

Water-Soluble Polymer Binders

PEG (Polyethylene Glycol) is a water-soluble polymer, and according to foreign literature, PEG is classified as a synthetic wax. It is prepared by stepwise addition of ethylene oxide to water or ethylene glycol, with a molecular weight range of 200-20000. PEG is completely soluble in water and has very low solubility in ethanol at room temperature (less than 1%). It is compatible with many substances and shows the greatest compatibility with substances with high polarity. It is non-toxic and non-irritating. The formability of PEG is equivalent to that of paraffin, and it has less residual carbon. Therefore, it can be considered a safe and environmentally friendly binder suitable for spray drying. However, PEG has a serious tendency to absorb moisture, and its moisture absorption capacity decreases with increasing molecular weight. It has very strict requirements for humidity and temperature in the working environment. After absorbing moisture, the powder becomes hard, the pressing pressure increases, and higher requirements are placed on the press. Additionally, it is more difficult to form some complex products.

Comparison in Actual Production

To compare the performance of the three binders, three batches of mixed materials were prepared using sodium butadiene rubber, paraffin, and PEG as binders. The basic composition of the mixture was WC-8%Co, and the blanks were compressed to the same weight and then sintered in a vacuum degassing integrated furnace to obtain metallographic and physical properties for comparison.

Experimental Section

The WC particle size used in this experiment was 6.5 m. The rubber used was sodium butadiene rubber, paraffin, and PEG.

The rubber and paraffin materials used aviation gasoline as the wet milling medium, while the PEG material used anhydrous alcohol as the ball milling medium. After ball milling, all materials were dried in a vacuum, screened, and granulated before pressing the compacts. They were then sintered under vacuum and pressure at a temperature of 1430°C.

From a direct analysis of the physical and mechanical performance data, it can be observed that the samples using paraffin and PEG as binders have increased strength and reduced magnetism, which is a significant advantage for mining carbides. Additionally, the metallographic photographs indicate that the microstructure using paraffin and PEG binders is more uniform compared to rubber binders. This is because paraffin and PEG have less residual carbon, while rubber binders are difficult to remove, leading to the growth of local grains due to the presence of a large amount of residual carbon.

Due to the lack of spray granulation equipment, the mixed materials using paraffin and PEG as binders were dried in a vacuum and then granulated using a manual screen. This had a significant impact on the pressing performance of the mixed materials, such as the accumulation of PEG in the drying process causing uneven distribution within the material, leading to agglomeration in the alloy phase. The poor effect of manually screening paraffin also posed a problem. However, from the perspective of the physical performance of the samples, it is still evident that PEG and paraffin have advantages over the rubber process.

During the experiment, the poor formability of paraffin due to manual screening was addressed by using manual weighing and pressing methods. However, in actual production, to accommodate large-scale production with self-pressing machines, increasing the pressing pressure and extending the holding time were necessary to avoid cracks or chipping of the paraffin material, which would reduce labor efficiency. Using a spray drying system to obtain a well-flowing mixture can effectively solve this problem.

The above discussion is a preliminary exploration of three commonly used binders in China. The research on binders is a systemic project involving a wide range of knowledge. To conduct in-depth research, one must possess knowledge in organic chemistry, polymer chemistry, and combine it with practical production knowledge of powder metallurgy to apply it to the production process of carbides. This will be a long-term and challenging task.

Wniosek

With the continuous expansion of research and application fields of carbide materials, such as the emergence of ultra-fine and nano-carbides, and the extensive use of metal ceramics and ceramic materials, the raw materials for these products have undergone significant changes compared to the previous ordinary carbides. They have smaller particle sizes, lower bulk densities, poorer fluidity, and much worse forming performance than ordinary carbides. Therefore, a more excellent binder is needed. Specifically, research can be initiated in the following three aspects:

1.Studying the interaction between different types of powder materials and binders to understand the impact on forming performance.

2.Developing new polymer binders with different characteristics by combining different components.

3.Researching the thermal cracking characteristics of binders to meet the requirements of carbide production processes in terms of process characteristics and residual carbon content.

Through the above three aspects of research, it is expected to obtain a new generation of binders with good forming performance, environmental friendliness, stable performance, no toxicity, and no residue at the molecular level.

A notable property of wood is its anisotropy, which leads to distinctions between longitudinal, transverse, end-wise, and transitional cutting during the machining of solid wood. Wood-based panels and wood composite materials are made from wood monomers, such as veneers, shavings, or fibers, which are combined with adhesives under specific temperatures and pressures to form a composite material. The properties of these materials are determined by the wood monomers, their arrangement, and the characteristics of the adhesive. The machinability also varies due to the structure and the proportion and nature of the additives. For example, medium-density fiberboard (MDF) is nearly isotropic, with almost equal cutting resistance across the board; particleboard, due to uneven density distribution and differences between the surface and internal structure, has significant variations in cutting resistance; and blockboard, composed of glued solid wood strips, has differences in grain direction between the strips, thus exhibiting both similar and different properties compared to solid wood during machining.

Selection of Wood Milling Cutter Structure

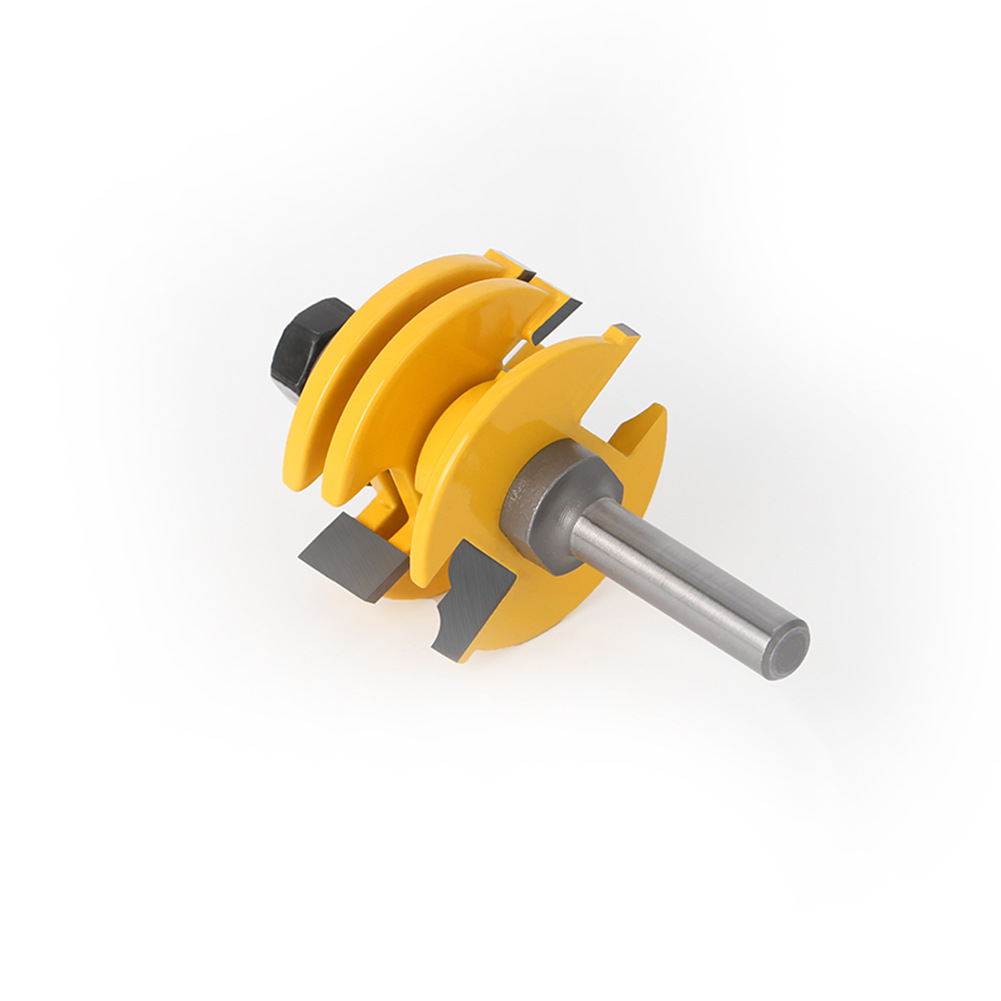

Based on the nature and requirements of the cutting object, a comprehensive consideration from both technical and economic perspectives is necessary to select the appropriate milling cutter structure. Options include solid wood milling cutters (Figure 3), welded solid milling cutters (Figure 4), assembled milling cutters (Figure 5), and combined milling cutters.

Selection of Milling Cutter Cutting Parameters (Table 1)

The cutting parameters of a milling cutter include the cutting speed of the cutter, the feed rate of the workpiece, and the milling depth. The cutting speed of the milling cutter depends on the cutter’s rotational speed and diameter. The feed rate of the workpiece depends on the requirements for the surface quality of the machined surface. The surface roughness of the workpiece is largely determined by the feed per tooth during the cutting process. If the feed per tooth is too large, the machined surface will be too rough; if the feed per tooth is too small, the machined surface may exhibit burn marks.

Depending on the different milling objects and surface quality requirements, the recommended feed per tooth for wood products processing is generally as follows: for rough machining, Uz = 0.8~1.5mm; for finish machining, Uz = 0.4~0.8mm. If the feed per tooth is within 0.1~0.3mm, there is a risk of the machined surface being burned. For all wood products, the common feed per tooth is Uz = 0.3~1.5mm. For a smooth surface, the feed per tooth Uz = 0.3~0.8mm; for a medium surface, Uz = 0.8~2.5mm; for a rough surface or when surface quality is not a concern, the feed per tooth Uz = 2.5-5.0mm.

Stability of Milling Cutter Operation

The stability of the milling cutter during operation is the basis for ensuring machining accuracy and surface quality. This includes two aspects: first, the vibration of the milling cutter during cutting due to external force excitation; and second, the deformation of the milling cutter under the action of external forces. Vibration is related to the structure of the milling cutter, the method of installation, and unbalanced mass. When the frequency of the external excitation force is close to the natural frequency of the milling cutter,the wood milling cutter will resonate, and the amplitude will increase significantly. A considerable portion of the milling cutters used for wood cutting are installed in a cantilevered manner. In this case, the static force due to the cutter’s own weight and the dynamic force generated by high-speed rotation act in combination on the cutter shaft. Under the action of this force, the cutter shaft will deform, producing a certain degree of deflection.

Since tool vibration and cutter shaft deformation will ultimately severely affect the surface quality of the workpiece, it is necessary to limit the unbalanced mass of the milling cutter and to avoid the cutter’s rotational frequency from matching its natural frequency. Additionally, for cantilevered cutter shafts, it is essential to limit the mass of the wood milling cutter, which means restricting the length and diameter of the cutter.

Safety of Milling Cutter Processing

The safety of wood milling cutter processing includes restrictions on the rotational speed of the milling cutter, limitations on chip thickness (Figure 6,7), restrictions on the profile height of shaped wood milling cutters, and limitations on the thickness and projection length of the blades for assembled wood milling cutters.

The characteristic of wood milling processing is high speed, with the rotational speed of the milling cutter often exceeding 3000rpm. High-speed cutting brings a series of safety issues. When the spindle speed of the milling machine reaches 9000rpm, the use of assembled milling cutters should be prohibited except for shank cutters with a diameter less than 16mm; strict non-destructive testing of the welds on welded solid milling cutters should also be conducted. When the milling cutter leaves the factory, the manufacturer has marked the maximum allowable speed on the body of the cutter, and the user must strictly adhere to this regulation; under no circumstances should the maximum allowable speed be exceeded.

The limitation on chip thickness is a necessary measure to prevent severe overload of the milling cutter due to excessive feed. According to the regulations of the German Association of Woodworking Machinery and Tool Manufacturers, for manually fed machines, the thickness of the milling chips should not exceed 1.1mm, and there are certain requirements for the width of the chip flute for different cutting milling cutters. For semi-mechanically fed machines, the maximum thickness of the milling chips should not exceed 10mm. For fully automatic, mechanically fed machines, there are no restrictions on the thickness of the milling chips and the chip flute, but general safety regulations must be observed.

For shaped milling cutters, the profile height of the shaping contour is closely related to the clamping method of the cutter, the thickness of the workpiece being cut, and the diameter of the cutter. Once the thickness of the workpiece, the diameter of the cutter, and the diameter of the center hole are determined, the profile height of the cutter reflects the cutter’s own strength and rigidity, as well as its ability to withstand cutting resistance. Therefore, there must be limitations on the profile height to ensure safety when using the cutter. On multi-axis milling machines (four-sided planers) and double-end wood milling machines or mortising machines, the spindle shaft diameter must not be less than 30mm. Moreover, due to the space limitation for installing the cutter, the height of the shaped contour cannot be too high.

When designing the body of an assembled wood milling cutter, the issue of blade clamping must be considered. Whether it is a cylindrical or disc-shaped body, the blade clamping form must ensure that it can provide a sufficiently large clamping force to counteract the rotational centrifugal force. For the integral blades or inserted welded blades clamped radially by the pressure plate, there must be a minimum limit on the projection length of the blade, as well as the thickness and length of the blade. When the thickness and length of the blade are less than this minimum limit, it means that the use of the wood milling cutter should be strictly prohibited. Otherwise, there will be safety risks. Figure 8 shows the projection length and the thickness and length of the blade for assembled wood milling cutters.

Preface

With the rapid development of China’s automotive industry, the new energy vehicle industry has experienced exponential growth in recent years. Lightweight is a core topic in the new energy vehicle industry, and the core of lightweight is the transformation of traditional materials. Aluminum alloys, with their high strength and light weight, are indispensable materials for lightweight automotive manufacturing. The geometric shapes of auto parts are relatively complex, and the proportion of die-cast aluminum alloy parts in the whole vehicle is increasing, as is the demand for CNC machining of die-cast parts.

The CNC manufacturing of aluminum alloy auto parts mainly requires high efficiency, high stability of continuous production, and continuously reducing costs, which necessitates more detailed control and planning of the entire production process.

Formation of Chip Build-up during Aluminum Alloy Machining

The main characteristic of aluminum in the machining process is its low melting point, which is manifested as “stickiness” in the working conditions. Due to this characteristic and insufficient cooling in actual working conditions, the heat generated by friction during the microscopic machining process cannot be released in a timely or effective manner. As a result, the aluminum melts and adheres to the cutting edge and chip flute of the cutter. When it cools, it instantly solidifies and adheres to the cutter, forming a chip build-up, leading to the scrapping of the cutter. This issue is commonly referred to in the industry as “easy to stick to the cutter.”

Cutters are a consumable in the CNC machining process and account for a significant portion of cost expenditures. The cutting edge of aluminum alloy-specific cutting tools should be sharper, and the chip flutes need special polishing treatment and an aluminum alloy-specific coating to improve the chip evacuation efficiency. The high-efficiency production in the automotive industry necessitates that cutters must increase feed rates and linear speeds, which in turn increases the heat generated during cutting, increases the risk of aluminum melting and sticking to the cutter, and leads to increased costs due to the scrapping of cutters caused by chip build-up.

With the requirements of environmental protection, the CNC machining of aluminum alloys extensively uses MQL (Minimum Quantity Lubrication) as a substitute for cutting fluids. The low melting point characteristic of aluminum, combined with the reduced cooling effect of MQL, further promotes the formation of chip build-up. Tools scrapped due to sticking account for about 409% of the total conventional scrapping of tools. Since traditional methods for dealing with chip build-up generally involve knocking or smashing, very few treated tools can be reused. Therefore, a new solution is proposed.

Treatment Measures

The specific treatment measures of the new solution are as follows:

Remove the cutter with existing chip build-up.

Find solid NaOH and dilute it with water, then place it in a ceramic container.

Once diluted into a NaOH solution, immerse the cutter with adhered aluminum into the solution, ensuring the aluminum-adhered parts are fully submerged, and continue for 2 hours, or prolong the immersion time based on the actual situation. A comparison of the traditional treatment method and the new solution is shown in Table 1.

Chemical Mechanism of Treating Chip Build-up

Taking the commonly used AIS7Mg material for automotive parts as an example, the content of Al is about 93.59%, the content of Si is 6.59%, and the content of Mg is 0.259%. Both Al and Si can react with NaOH solution. Soaking in NaOH solution can remove the main Al components remaining on the cutter. The principle is that the metal reacts with NaOH to produce bubbles (5), which eventually causes the adhered aluminum to fall off. The chemical reaction equations are as follows:

The reaction equation between Si and NaOH is:

Si + 2NaOH + H?O = Na?SiO? + 2H?↑

The reaction equation between Al and NaOH is:

2Al + 2NaOH + 6H?O = 2NaAl(OH)? + 3H?↑

Final conclusion: The aluminum is removed, and the cutting tool can be reused.

Experimental Verification

The above theory was tested using taps. The reason for choosing taps is that in aluminum alloy machining, taps are among the higher-value cutters and are tasked with a longer service life mission. Moreover, their geometric shape is complex, and the grooves are narrow, making it basically impossible to clear the adhered aluminum using physical methods after the sticking phenomenon occurs. Testing this type of cutter is more meaningful and representative.

Due to the high heat generated during machining and possible insufficient cooling, the aluminum is instantly melted and sticks in the grooves, indicating that the tap can no longer be used, and the thread profile is damaged.

According to the above chemical theory, the tap with adhered aluminum (chip build-up) was completely soaked in NaOH solution. After complete immersion in NaOH, the tap was visually inspected, and the chip build-up in the grooves had completely fallen off, with residual aluminum debris in the experimental vessel. The treated tap was used again to machine workpieces, and the thread profile of the workpiece was found to meet the requirements, with the thread being qualified. The tap could be reused.

Wniosek

The automotive parts industry is characterized by mass production. The matching of new equipment and specially designed cutters requires a large amount of cutting verification during the initial setup. During the verification process, due to factors such as parameter matching, the breaking-in of new equipment, and the inexperience of the debugging personnel, the phenomenon of chip build-up on cutters is relatively common, leading to a straight-line rise in scrapping costs and production cycles. Additionally, issues such as changes in blank allowances and momentary cooling instability during the later stages of mass production, which lead to aluminum adhesion, have been effectively resolved after applying this method. This has greatly saved on cutter costs and processing time, increased the service life of the cutters, and significantly reduced the production costs for the enterprise.

]]>

Experimental Method

Recycled WC powder with a Fisher particle size of 3.00~10.00 μm and normal WC powder with a Fisher particle size of 10.00~18.00 μm were mixed with Co powder or Ni powder with a loose packing density of 0.5~0.7g/cm3 to prepare mixtures of grades YJ1, YJ2, N309, etc. The mixtures were shaped, degummed, and then sintered in a domestically produced horizontal vacuum furnace and a low-pressure hot isostatic pressing furnace manufactured by a German specialized equipment company. The low-pressure hot isostatic pressing process is as follows: loading → vacuum pumping → heating → maintaining sintering temperature → charging argon and pressurizing → maintaining pressure and temperature → cooling and depressurizing → unloading. Electron microscopy was used for metallographic analysis, and the linear shrinkage and shrinkage rate of the samples during the sintering process were measured by the low-pressure hot isostatic pressing sintering furnace to analyze the densification process. The test alloys were made into D43×22 straight horseshoe bits for calibration tests in mining operations.

Experimental Results

Comparison of Properties

Between Low-Pressure Hot Isostatic Pressing Treatment of Recycled Material and Vacuum Sintering Treatment of Normal Material. The two types of tungsten carbide powders, recycled and normal, were processed using the same manufacturing process, undergoing vacuum sintering and low-pressure hot isostatic pressing treatment, respectively. The results are listed in Table 1.

As can be seen from Table 1, the porosity of the alloy treated with low-pressure hot isostatic pressing using recycled WC powder is even lower than that of the normal alloy, and its performance has been significantly improved, with an increase in the transverse rupture strength value; moreover, the elimination of type B pores ranging from 10 to 25 μm indicates the intrinsic relationship between the reduction in porosity and the increase in transverse rupture strength, while also confirming the capability of low-pressure hot isostatic pressing sintering to eliminate pores in recycled alloys.

Low-Pressure Hot Isostatic Pressing Alloy Linear Shrinkage Test

The linear shrinkage and shrinkage rate of the samples during the sintering process in the low-pressure hot isostatic pressing furnace were measured as shown in the attached figure. The alloy undergoes two stages: vacuum sintering and hot isostatic pressing. The macroscopic pores are eliminated during the vacuum sintering stage, and the microscopic pores are eliminated during the hot isostatic pressing stage to achieve the final densification level.

Comparison of On-site Rock Drilling Effects

The two types of tungsten carbide?powders, recycled and normal, were made into alloys of grades YJ1, YJ2, N309, etc., and calibration tests were conducted at the Taolin Lead-Zinc Mine. The results are listed in Table 2.

The rock drilling calibration indicates that high-quality mining carbide?can be produced from recycled WC powder through low-pressure hot isostatic pressing treatment, and their performance is comparable to that of mining carbide?made from normal tungsten carbide.

Result Analysis

Process Characteristics of Low-Pressure Hot Isostatic Pressing for Eliminating Pores in Recycled carbide

The densification of carbide?primarily occurs during sintering, where the plastic flow of the binder phase and the rearrangement of WC grains are driven by surface tension. However, under atmospheric or vacuum sintering, a certain amount of porosity always remains after shrinkage densification is complete; this is because when pores are sealed, the stress inside the pores reaches equilibrium with the surface tension of the pores. Additionally, due to the mixed composition of recycled materials and the presence of more harmful impurities, large pores and voids are easily formed during vacuum sintering, leading to issues such as low alloy density, low fracture strength, significant hardness variations, and severe contamination of the alloy. Applying a certain pressure can promote further flow of the binder phase and rearrangement of WC grains, thereby greatly reducing or even completely eliminating these pores or voids.

Study on the Densification Mechanism of Low-Pressure Hot Isostatic Pressing

The change curve of the linear shrinkage rate of recycled carbide?samples during low-pressure hot isostatic pressing sintering is shown in the attached figure. There are three peaks on the shrinkage rate curve: Peak A appears at a sintering temperature of 1200°C, which is solid-phase sintering. Due to the low yield point of the binder phase, plastic flow occurs under a small external force. The flow of the binder metal changes the contact situation between powder particles, causing the carbide?particles to move and come closer together. Peak B appears during the liquid-phase sintering process at 1340°C, where WC particle rearrangement, solution precipitation, and skeleton formation result in significant shrinkage of the sintered body, and macroscopic pores are eliminated during the vacuum sintering process of low-pressure hot isostatic pressing. Peak C appears at the beginning of the pressurization stage, where the rise in pressure eliminates the micro-pores in the product. However, with the extension of the pressure maintenance time, no new shrinkage peak appears in the product.

Wniosek

(1) The physical and mechanical properties of the recycled alloy treated by low-pressure hot isostatic pressing are superior to those of alloys manufactured by conventional processes, with a significant reduction in porosity and the elimination of type B pores.

(2) The recycled alloy treated by low-pressure hot isostatic pressing does not fall short of normal alloys in on-site rock drilling tests, and its wear resistance is even improved.

(3) The mechanism by which low-pressure hot isostatic pressing improves the performance of the alloy is mainly the elimination of large-sized pores and the reduction in porosity.

]]>

Spherical cast tungsten carbide powder is a new type of ultra-wear-resistant ceramic particle material. Compared with traditional tungsten carbide, spherical cast tungsten carbide has two significant advantages: first, it has a regular spherical appearance, good powder flowability, and wettability, which results in good integration with the surrounding tissue when added as particles, reducing the likelihood of stress concentration; second, the internal structure of the tungsten carbide particles is dense, with good toughness, fine grains, high hardness, and the coating has excellent wear resistance and is less likely to break under load. Due to its outstanding performance, spherical cast tungsten carbide powder is gradually replacing traditional tungsten carbide powder in the surface protection of components in mining machinery, oil machinery, construction industry, and foundries, significantly improving the wear resistance, corrosion resistance, and oxidation resistance of workpieces, and extending the service life of workpieces.

Introduction to the Methods of Spherical Cast Tungsten Carbide

Currently, the spherical cast tungsten carbide powders available in the market are mainly prepared by the following methods: induction remelting spheroidization, plasma remelting spheroidization, and plasma rotating electrode atomization.

The induction remelting spheroidization method involves heating the material in a reactor to the spheroidization temperature through induction heating, and the material moves forward slowly the vibration of the furnace tube. If the dispersion of the material is not well controlled, the molten droplets will grow due to collision and adhesion, making particle size control difficult. Moreover, during the operation, the powder must not come into contact with the reactor, otherwise it will affect the entire spheroidization process and cause material waste.

The plasma remelting spheroidization method uses casting tungsten carbide powder as the raw material and employs radiofrequency plasma flame to heat argon gas to a high temperature of 3000 to 10000 ℃, melting the casting tungsten carbide particles into a liquid state and directly quickly condensing them into spherical particles. This method can easily obtain fine-grained spherical tungsten carbide powder by controlling the particle size and composition of the raw material.

The plasma rotating electrode atomization method uses a tungsten carbide rod as the electrode, fixed within the rod material bin, and then subjected to plasma atomization under inert gas protection. The plasma arc melts the end face of the high-speed rotating rod, and under the action of centrifugal force, the molten droplets separate from the edge of the molten pool and solidify in the form of spherical particles. This technology avoids the difficulty of material dispersion at ultra-high temperatures during remelting spheroidization, and the obtained spherical tungsten carbide powder has a narrow particle size distribution range and is easy to control.

The following will study the chemical composition, micro-morphology, microstructure, microhardness, and other powder properties of spherical cast tungsten carbide powders prepared by different methods.

Chemical composition

The table above shows the chemical composition of spherical cast w?glik wolframu powder samples prepared by different methods. It can be observed that the main components of the spherical cast tungsten carbide powder are W and C elements, and all contain trace amounts of Fe, V, Cr, and Nb elements. The ideal spherical cast tungsten carbide should be a eutectic of WC and W2C, with an eutectic temperature of 2525 ℃ and a carbon content of 3.840% (by mass) at the eutectic point. From the data in the table, it can be seen that the total carbon content of the spherical cast tungsten carbide prepared by the plasma rotating electrode atomization method has the smallest deviation from the theoretical eutectic carbon content, with the lowest free carbon content; the powder obtained by the induction remelting spheroidization method has the largest difference in total carbon content from the theoretical value, with a difference of 0.170% (by mass). This is due to the carbon content increase caused by the graphite tube heating method used in the induction remelting spheroidization process. In addition, by comparing samples 2#, 3#, and 4# with similar particle sizes, it can be determined that the powder prepared by the plasma rotating electrode atomization method has the relatively lowest impurity content. However, the impurity content of sample 1# prepared by the plasma rotating electrode atomization method is relatively high, which may be related to the quality of the cast tungsten carbide raw material rod. This suggests that, compared to other methods, the plasma rotating electrode atomization method can more accurately control the carbon content of spherical cast tungsten carbide powder, preventing overeutectic and hypoeutectic reactions caused by carburization and decarburization, and obtaining a nearly complete eutectic structure, which is crucial for improving the microstructure and properties of spherical cast tungsten carbide.

Microscopic morphology

The image above shows the microscopic morphology of spherical cast tungsten carbide powders prepared by different methods. It can be observed that the spherical cast tungsten carbide powders prepared by the three methods are all regular and smooth, nearly spherical in shape.

The image above shows the cross-sectional photos of spherical cast tungsten carbide powders prepared by different methods. As can be seen from (a) and (b), the spherical tungsten carbide powder particles prepared by the plasma rotating electrode atomization method are dense with almost no defects. However, as seen in (c) and (d), there are some obvious pores within the spherical tungsten carbide powder particles prepared by the plasma remelting spheroidization method and the induction remelting spheroidization method, resulting in some hollow powders. The main reason for this is that the crushed tungsten carbide powder material used in the above methods is likely to contain residual pores from the casting process. During the short plasma or induction heating process, the interior of the crushed tungsten carbide powder is difficult to completely melt, leading to some residual pores within the particles.

Microstructure

The image above shows the microstructure photos of spherical cast tungsten carbide powder particles after corrosion. It can be observed that the internal structure of the spherical tungsten carbide powder particles prepared by the three methods mainly consists of a typical fine acicular WC and W2C eutectic structure. Compared to the plasma remelting spheroidization method and the induction remelting spheroidization method, the spherical cast tungsten carbide powder prepared by the plasma rotating electrode atomization method has a denser eutectic structure. This is because, unlike the plasma remelting spheroidization method and the induction remelting spheroidization method, the plasma rotating electrode atomization method completely melts the cast tungsten carbide feedstock rod and then solidifies by being thrown out under the action of centrifugal force. During the crystallization of the molten cast tungsten carbide, the degree of undercooling is greater, nucleation is more rapid, and a larger number of crystal nuclei are generated, resulting in a finer and denser eutectic structure.

Microhardness

The table below shows the average microhardness of spherical cast tungsten carbide powders prepared by different methods. It can be seen that the microhardness of the spherical cast tungsten carbide powders prepared by the three methods is all above 2800 HV0.1, with the powder prepared by the plasma rotating electrode atomization method having the highest microhardness, reaching 3045 HV0.1. This is mainly due to the finer eutectic structure within the spherical cast tungsten carbide prepared by the plasma rotating electrode atomization method.

Other Physical Properties of spherical cast tungsten carbide

The table below shows the flowability and apparent density values of spherical cast tungsten carbide powders prepared by different methods. It can be seen that the powder prepared by the plasma rotating electrode atomization method has the worst flowability and the smallest apparent density; whereas the powder prepared by the induction remelting spheroidization method has the best flowability and the largest apparent density.

Wniosek

(1) The spherical cast tungsten carbide prepared by the plasma rotating electrode atomization method has the smallest deviation from the theoretical eutectic carbon content, the lowest free carbon content, and relatively low impurity content.

(2) The spherical tungsten carbide powder particles prepared by the plasma rotating electrode atomization method are dense with almost no defects, and the eutectic structure is finer. The spherical tungsten carbide powder particles prepared by the plasma remelting spheroidization method and the induction remelting spheroidization method both have some obvious pores, resulting in some hollow powders.

(3) The spherical cast tungsten carbide powders prepared by the three methods mainly consist of WC and W2C phases.

(4) The microhardness of the spherical cast tungsten carbide powders prepared by the three methods is all above 2800 HV0.1, with the powder prepared by the plasma rotating electrode atomization method having the highest microhardness, reaching 3045 HV0.1. The powder prepared by the induction remelting spheroidization method has the best flowability and the largest apparent density.

]]>The main body of the part is a weak stiffness structure, which is prone to instability during mechanical machining, especially when machining the outer wall of the ring and clamping the thin-walled ring.

Machining Analysis

The morphology of the typical weak thin-walled ring with a composite structure of bilateral axial supporting parts after machining with general mechanical machining techniques is shown in Figure 2. The following deficiencies are observed:

(1)Obvious tool marks in the middle of the bilateral axial supporting parts. The upper and lower parts of the bilateral axial supporting parts are formed during two separate machining steps: milling the shape of the thin-walled ring and milling the shape of the bilateral axial supporting parts. Due to the non-coincidence of the process benchmarks between the two steps, obvious tool marks appear in the middle of the bilateral axial supporting parts.

(2)Prominent vibration marks in the middle of the thin-walled ring shape. The wall thickness of the middle part of the ring body is 2mm, which results in significantly insufficient stiffness. During the machining of the thin-walled ring shape, the middle part is prone to instability, leading to the formation of obvious vibration marks. The superposition of these issues collectively results in the machining instability problem becoming a production bottleneck.

Process Optimization

To address the deficiencies of general mechanical machining techniques, a series of compound machining measures have been adopted, including the conversion control of process benchmarks to “bore-face-contour,” the gradual reduction of workpiece stiffness during machining, the reinforcement of stiffness combined with damping and vibration absorption, and the maximization of clamping area and stiffness. These measures aim to achieve stable machining of the weak thin-walled ring with the composite structure of bilateral axial supporting parts.

Precision Conversion of Process Benchmarks

(1) After rough machining the inner shape and end face, precision turn the inner circle and end face to form the process benchmark “bore-face.”

(2) The specific steps for milling the contour positioning benchmark are as follows.

1)Clamp the fixture in the vise (see Figure 3). The bottom surface of the fixture is aligned with the workpiece end face, and the cylindrical surface of the fixture is aligned with the axial direction of the workpiece inner circle. Use a dial indicator to align the fixture bottom surface with a flatness of ≤0.01mm and then secure it.

2) Clamp the workpiece on the fixture (see Figure 4). The workpiece end face and inner bore are tightly against the fixture’s positioning surface and are clamped with a pressure plate.

3)Symmetrically machine two identical precision milling positioning steps on the workpiece contour (see Figure 5). The step height is 20mm, which converts the process benchmark from “bore-face” to “contour.”

Steady-state Machining Control

(1) The specific steps for milling the thin-walled ring contour are as follows.

1)Clamp the workpiece with a vice on the precision milling positioning step (see Figure 6).

2) Embed polytetrafluoroethylene or nylon washers into the internal thread relief groove of the workpiece, and then use an external thread mandrel to screw into the internal thread of the workpiece to enhance the stiffness of the annular body cavity.

3) Machine the round corners of the bilateral supporting parts and the shape of the thin-walled ring (see Figure 7).

(2) The specific steps for milling the shape of the bilateral axial supporting parts are as follows.

Turn the workpiece around, and use an external thread mandrel (see Figure 8) to screw into the internal thread of the workpiece to enhance the stiffness of the annular body cavity.

Clamp the workpiece with a clamping block (see Figure 9), and secure it with a flat-nose pliers.

Perform finish machining on the shape of the bilateral axial supporting parts (see Figure 10).

(3) The specific steps for milling the outer step of the bilateral supporting parts?are as follows.

Clamp the fixture with a flat-nose pliers (see Figure 11).

Axially compress the thin-walled ring body of the workpiece with the fixture (see Figure 12).

Press the expanding ring into the inner circle of the workpiece’s thin-walled ring and align the inner circle of the expanding ring with the edge finder.

Machine the structures such as the outer side of the bilateral supporting parts, the step, chamfer, and thread to completion.

Machining Process

According to the optimized process plan, the specific machining process is as follows.

(1) Milling the profile positioning reference: The milling process for the profile positioning reference is shown in Figure 13.

(2) Milling the shape of the thin-walled ring: The shape of the thin-walled ring after milling is shown in Figure 14.

(1) To reduce the alloy’s sensitivity to sintering temperature fluctuations and carbon content changes, and to prevent the uneven growth of carbide grains;

(2) To change the phase composition of the alloy, thereby improving the structure and properties of the alloy.

This paper reviews the effects of adding rare earth elements, metals, and metal carbides to cemented carbides on their properties.

The Effect of Adding Rare Earth Elements on Carbide Properties

Rare earth elements are the 15 lanthanide elements with atomic numbers ranging from 57 to 71 in the third subgroup of the Mendeleev periodic table, plus scandium and yttrium, which have similar electronic structures and chemical properties, totaling 17 elements. Rare earths are known as the “treasure trove” of new materials and are a group of elements of particular concern to scientists worldwide, especially material experts. The following sections discuss the effects of adding rare earth elements on the hardness, bending strength, and grain size of cemented carbides.

1.1 Hardness

Whether the addition of rare earths has a significant effect on the hardness of the alloy is an issue of concern. The influence of yttrium and lanthanum on WC-TiC-Co cemented carbides is not significant, but different rare earth elements have different trends; however, the hardness of alloys with Nd or Ce added, regardless of the content, is slightly higher than that of the untreated alloys, with an average increase of 0.3 HRA units. For YG6 alloys, the addition of mixed rare earths results in a decrease in hardness to varying degrees when the content reaches 1%; for YT? alloys, the hardness remains largely unchanged or slightly increased with the addition of La or Y.

1.2 Bending Strength

Data shows that adding a certain amount of rare earth elements to the alloy can increase its bending strength. After the addition of rare earth oxides, the strength of the alloy is improved due to the dispersion strengthening of nickel by the rare earth oxides. When the content of rare earths is 1.2% to 1.6% of the binder metal content, the bending strength of the alloy reaches its maximum value; after adding mixed rare earth oxides equivalent to 0.25% to 1.00% of the binder mass fraction, the bending strength of the WC-8%Co alloy is improved to some extent. When the addition amount is 0.25% to 0.50%, the bending strength can be increased by 1.5%, but excessive addition of rare earths will lead to a decrease in bending strength.

1.3 Grain Size of Carbides

A large number of literature reports have been published on the effect of rare earths on the WC grain size in cemented carbides, but there is no unified conclusion to date. Regardless of the type of rare earth element added, the carbide grains in the alloy are finer than those without additives, and as the amount added increases, the refinement becomes more pronounced, and the grain size of the rare earth element-added alloy appears more uniform than that of the untreated alloy; studies have shown that the addition of trace rare earth elements does not affect the particle size of tungsten carbide and the binder phase.

Through extensive observation of the WC grain size and microstructure of WC-Co-TiC-TaC with rare earths and WC-Co with rare earths alloys, it is believed that the effect of rare earths on the WC grain size of cemented carbides is determined by two refinement effects and one growth effect. Table 1 shows the comparison of properties between rare earth alloys and alloys without rare earths.

2 The Effect of Adding Metals on the Properties of Cemented Carbides

Commonly used metal additives include chromium, molybdenum, tungsten, tantalum, niobium, copper, aluminum, and others. Except for copper and aluminum, all of these can form carbides. Therefore, the change in the carbon content of the alloy must be considered when adding these metals.

2.1 Adding Noble Metals

Sintered cemented carbide products with added noble metals such as Ru, Rh, Pd, and Re exhibit high wear resistance and corrosion resistance and can be used in corrosive and abrasive media. Noble metals do not form carbide phases and exist in the binder metal as solid solutions. Ru and Re cause the formation of a substructure in the binder phase of the cemented carbide. Alloying sintered cemented carbides with noble metals can increase the microhardness and elastic modulus of the binder phase, while also improving the bending strength, compressive strength limit, and yield point of the sintered cemented carbide as a whole.

2.2 Adding Copper

The addition of a small amount of copper to alloys used in mining can both increase the strength of the alloy and improve its impact toughness. Research results indicate that after adding a small amount of copper to the WC-13% Fe/Co/Ni alloy, the hardness of the alloy slightly decreases, but the bending strength is significantly improved. When the copper content is around 0.8%, the alloy exhibits the best performance. Moreover, copper also has the effect of refining and spheroidizing WC grains.

2.3 Adding Alkali Metals

Alkali metals can promote the growth of toaleta grains, but their effect is limited by other factors. For instance, in the presence of silicon, sodium actually refines the WC grains; whereas if sodium is present during the carbonization process, the WC grains will become finer. Adding industrial-grade Li?CO? with a purity of 98% to 99% to the alloy results in a cemented carbide with coarser average grains, clear and well-defined grain edges, and high bending strength.

2.4 Adding Aluminum

The effect of adding a small amount of Al on the properties and structure of the WC-13% Fe/Co/Ni cemented carbide shows that the addition of a small amount of aluminum can refine the WC grains. While the hardness of the alloy increases by 2 to 3 HRA, the bending strength of the alloy can be improved by 100 to 200 MPa. When the amount of Al added exceeds 0.8%, the bending strength of the alloy decreases, which is due to reasons such as the enrichment of martensite at the phase interface and the relative change in the amount of γ phase. Table 2 shows the effect of metal additives on the properties of the alloy.

]]>

Currently, in mechanical manufacturing, due to the rapid updating and upgrading of products, there are higher requirements for the selection of parts. Particularly in the manufacturing of industries such as aerospace, large power stations, and ships, some difficult-to-machine materials like high-temperature alloys, titanium alloys, heat-resistant stainless steels, and composite materials have been widely used. Among them, the efficient processing of widely used and commonly employed high-temperature alloy materials has received more attention.

Using high-performance high-speed steel bimetal saw blades (with M42 as the edge material) to cut difficult-to-machine high-temperature alloys results in low cutting efficiency and a very short service life. Subsequently, saw blades made of cemented carbide with high hardness were chosen. Through testing and practical application, cemented carbide saw blades have achieved significant results in the blanking processing of high-temperature alloys, meeting the requirements of production schedules.

Design and Selection of Cemented Carbide Saw Blades

Cemented carbide saw blades have different materials and structures. In practical applications, we have found that not every type of cemented carbide saw blade can achieve good results in the blanking processing of high-temperature alloys. Only by making reasonable choices and using them properly can the desired results be obtained. Therefore, we have selected and compared four aspects: the structure of the saw blade, the form of the tooth shape, the material, and the reasonable selection of cutting parameters. The details are as follows:

Tool Structure

Cemented carbide saw blades typically adopt a tipped and welded structure. The tips of the teeth on cemented carbide saw blades have the advantages of high hardness, high wear resistance, and high fatigue resistance. However, their main drawbacks are brittleness, low strength, and poor resistance to impact.

After testing and comparative application (especially based on the final sawing blanking data comparison results), we believe that for the blanking of high-temperature alloys, the saw blade structure is best suited with coarse teeth and variable pitch cemented carbide saw blades. The reason we believe this is optimal is that during the sawing blanking of high-temperature alloys (particularly nickel-based high-temperature alloys), the chips have strong adhesion, making it difficult for the chips to be discharged smoothly. The intermittent formation and disappearance of built-up edge can easily cause the cutting edge to chip and the tool’s flank wear to intensify. Choosing coarse teeth not only increases the strength of the cutting edge but also enlarges the chip space, facilitating the use of a larger feed rate to improve cutting efficiency. The adoption of variable pitch can reduce cutting noise and vibration, making the cutting process more stable, which is beneficial for improving the durability of the tool. A schematic diagram of the variable pitch saw blade structure can be seen in Figure 1.

Selection of Tool Tooth Shape

Common tooth shapes for saw blades include standard teeth, hook-shaped teeth, and trapezoidal teeth, as shown in Figure 2.

- Standard teeth have a cutting approach angle g=0°, with the tooth face perpendicular to the substrate, and the tooth slots are deep and narrow.

- Hook-shaped teeth have a cutting approach angle g=5°~10°, with the tooth slots deep and wide.

- Trapezoidal teeth have a cutting approach angle g=10°~15° and a back angle a=6°~8°, providing high tooth strength, suitable for heavy cutting.

For the processing of high-temperature alloy materials, in addition to selecting high-strength cemented carbide materials for the saw blades, the choice of tooth shape is also very important. Trapezoidal teeth have sufficient strength and are less prone to chipping during cutting. Due to the larger approach angle, the cutting resistance is also smaller than that of standard straight teeth. Practical verification has also proven that the choice of trapezoidal teeth results in better cutting performance compared to the other two tooth shapes.

Tool Material Grades

The grades of cemented carbide suitable for cutting high-temperature alloy materials mainly fall into two categories: Type M and Type K according to the ISO standard (now recommended as Type S). Based on the results of sawing comparison tests, the improvement in cutting efficiency between the two types of tool grades is not significant. However, in terms of sawing service life, the saw blades made of material equivalent to grade M15-M30 have a 15%~20% longer life span compared to those made of material equivalent to grade K05-K20 (when processing high-temperature alloys of the same specification and grade).

Selection of Cutting Parameters

The rational selection of cutting parameters is crucial for the blanking of high-temperature alloys. Proper cutting parameters ensure normal blanking of workpieces, significantly improve cutting efficiency and tool life, and also reduce the harsh noise generated by the adhesion and friction of chips between the tool and the workpiece during blanking. Based on our experimental application results for various nickel-based high-temperature alloy grades (considering efficiency and tool life comprehensively), the selected rational cutting parameters are as follows:

Cutting linear speed: 15~20 m/min

Feed rate (material removal rate): 6~8 cm2/min

The above cutting parameters have been determined through long-term experimental applications and are considered to be economically viable.

Actual Tool Benefits

Through the aforementioned four aspects of work, the use of cemented carbide saw blades for processing high-temperature alloys has achieved significant economic effects in the steam turbine factory:

After testing and comparing multiple data results, the current cemented carbide saw blades used for processing high-temperature alloys have improved the cutting efficiency by 5 to 8 times compared to the previously used bimetal saw blades. For example, when processing a GH4169 nickel-based high-temperature alloy blank with dimensions of 140×245, the original M42 bimetal saw blade took about 6 to 8 hours to blank one piece. However, with the selected cemented carbide saw blade for processing high-temperature alloys, the blanking time for one workpiece is only about 1 hour. Moreover, what is more prominent is the improvement in tool life.

When processing blanks of the above-mentioned grades and specifications, the original M42 bimetal saw blade could only blank one piece, whereas the current cemented carbide saw blade can generally blank 20 to 24 pieces (under reasonable cutting parameters and proper operation, one saw blade can even blank 40 to 50 pieces). Although the price of the current cemented carbide saw blade is about 5 times higher than that of the bimetal saw blade, in terms of cost-performance ratio and comprehensive economic benefits (especially as demonstrated by the comparison of the above typical example), using cemented carbide saw blades to process high-temperature alloys is very cost-effective. It achieves the goal of low cost, high tool life, and efficient processing.

Use of Cemented Carbide Saw Blades

Using cemented carbide saw blades for sawing and blanking high-temperature alloy materials is an efficient and ideal process method. However, improper use can lead to rapid wear of the saw blade’s teeth and even cause the saw belt to break, which not only fails to achieve the expected results but may also result in significant losses. Therefore, the correct use of cemented carbide saw blades is very important. There are strict requirements for using saw blades, which are mainly in the following three aspects:

Requirements for the Machine Tool

a. The sawing machine must have good rigidity and a certain level of accuracy to meet the requirements for stable processing with cemented carbide saw blades.

b. Select a sawing machine with a suitable power and specification based on the diameter (cutting area) of the workpiece.

c. The machine tool must be equipped with a good chip removal, cooling system, and saw blade guiding device.

Requirements for Operating the Use of Cemented Carbide Saw Blades

a. The workpiece must be clamped securely, and after clamping, check whether the clamping points (surfaces) are in the middle and upper part of the workpiece to ensure stability during processing.

b. Break-in of the saw blade: New saw blades must go through a break-in period before normal cutting to prevent premature damage to the teeth. After the break-in process, the teeth will wear normally; without it, the teeth will be destroyed prematurely. The feed rate during the break-in period should be 20%~30% of the normal feed rate.

c. Selection of tension force:Excessive tension can cause the saw belt to break; insufficient tension can damage the saw belt or cause cutting deviation. When using a cemented carbide band saw, the tension must be adjusted to 2200~2500 kg/m2.

d. Cooling and chip flushing during cutting: When using a cemented carbide band saw to blank high-temperature alloy materials, in order to reduce the cutting temperature, cutting resistance, and extend the life of the band saw, water-based extreme pressure cutting fluid must be continuously applied during sawing. Additionally, the chips produced during sawing should be cleaned synchronously with a steel brush.

Rational Selection of Cutting Parameters

For blanking high-temperature alloy blanks, the selection of cutting parameters directly ensures the normal progress of sawing. Reasonable cutting parameters also achieve higher cutting efficiency and tool life. Due to the poor machinability of high-temperature alloy materials, the cutting parameters should be much lower compared to other alloy steel materials. Practice has proven that the cutting parameters recommended in the above examples are more reasonable. If the feed rate (material removal rate) is too low, the wear on the flank of the tool will increase. Moreover, increasing the cutting speed and feed rate will also increase the cutting force and cause the chip slot to clog, leading to chipping and reduced tool life.

]]>This paper takes WC-12Co cemented carbide as the research object. Firstly, nano WC-Co composite powders were prepared by in-situ reduction carbonization reaction at different temperatures, and the composite powders were rapidly densified by discharge plasma sintering technology. The sintered blocks were systematically studied to analyze the effect of the in-situ reduction carbonization reaction temperature on the distribution characteristics of special crystal planes.

Experiment

The raw materials used in the experiment were carbon black, blue tungsten (purity 99.5wt.%, average particle size 50μm) and cobalt oxide (purity 98.5wt.%, average particle size 35μm). Carbon black, blue tungsten, and cobalt oxide were weighed according to the proportion for generating WC-12Co powder, and high-energy ball milling was carried out in a hard alloy ball mill jar with ethanol as the ball milling medium. The mixed powders were subjected to in-situ reduction carbonization reaction at 850°C, 900°C, and 1000°C in a vacuum environment, with a holding time of 1 hour. 2wt% of grain growth inhibitor was added to the composite powders prepared by in-situ reaction, and discharge plasma sintering densification was carried out. The sintering temperature was 1080°C, the holding time was 5 minutes, and the sintering pressure was 60MPa.

Materia? phase analysis was carried out on a Rigaku D/max-3c X-ray diffractometer with an acceleration voltage of 35kV and a current of 30mA, and a scanning rate of 2°/min. The micro-morphology of the powder was observed on a FEI-NovaNano SEM field emission scanning electron microscope.

Results and of Crystal Plane Distribution

Figure 1 shows the thermogravimetric (TG-DSC) curves of the nano WC-Co composite powder synthesized by in-situ reaction when heated to 1000°C at a heating rate of 10°C/min under Ar gas protection. From the change in the TG curve, it can be seen that as the temperature increases, the mass of the in-situ synthesized WC-Co composite powder decreases. When the temperature reaches 1000°C, the reaction ends, and the powder weight loss reaches nearly 6%. Throughout the heating process, the mass loss of the composite powder is divided into two stages: the first stage is from room temperature to 190°C, where there is a significant decrease in powder mass due to the ease of gas adsorption by nanoscale powders, and the gas desorbs and releases during the heating process, causing powder weight loss; the second stage is from 628°C to 1000°C, where the weight loss rate decreases from high to low. This is because the composite powder did not fully react during the low-temperature in-situ reduction carbonization reaction, and a secondary reaction occurred during the heating process, resulting in rapid weight loss of the powder.

Figure 2 shows the nanoscale WC-Co composite powder prepared by in-situ reduction carbonization reaction at 850°C. The powder particle size is mainly distributed between 30~120nm, with an average particle size of ~83.4nm. The particles have a good sphericity, and spherical or quasi-spherical powders exhibit good dispersibility and flowability, which can effectively avoid hard agglomeration of the powder. This is beneficial for the uniform dispersion of the powder in the sintering mold, thereby ensuring the uniformity and density of the sintered bulk structure. The composite powder prepared by the in-situ reduction carbonization reaction is subjected to rapid sintering densification in an SPS system to obtain nearly fully dense WC-Co cemented carbide blocks. XRD tests are conducted on the alloy specimens in the direction perpendicular to the sintering pressure and in the direction parallel to the sintering pressure. The relative integral intensities (i.e., integral area) of the diffraction peaks for each crystal plane in the VD (vertical to the sintering pressure) and PD (parallel to the sintering pressure) planes of the specimens are obtained through fitting calculations and compared with the relative intensities (integral area) of the diffraction peaks for each crystal plane in the PDF card (which represents the diffraction peak intensity distribution characteristics of traditional sintered cemented carbides), as shown in Table 1. The results indicate that the sintered WC-Co cemented carbide block specimens exhibit a significant characteristic of high anisotropic distribution for specific crystal planes.

Figure 3 shows the XRD patterns of the VD (vertical to the sintering pressure) and PD (parallel to the sintering pressure) planes of the specimens obtained by SPS sintering of the nanoscale WC-Co composite powder prepared by in-situ reaction at 850°C. From the figure, it can be observed that on the PD plane, the intensity of the (0001) plane peak is lower, while the intensity of the (10-10) plane peak is relatively higher. By fitting and calculating the integral area of each diffraction peak, the relative integral area of each crystal plane and the proportion of each crystal plane’s integral area in the total integral area are obtained, as shown in Figures 5 and 6.

From Figure 5, it can be seen that on the PD plane, the integral area of the (0001) plane accounts for only 10.72% of the total integral area, which is a decrease of 3.3% from the 14.02% in the PDF card (as shown in Figure 4). The proportion of the (10-10) plane reaches 35.73%, which is higher than the 31.87% in the PDF card, and the proportion of the (10-11) plane decreases to 21.76% compared to the 28.11% in the PDF card. Compared to conventional cemented carbide samples, in the PD direction of the composite powder sintered block prepared by in-situ reaction at 850°C, the distribution proportion of the main characteristic planes (0001) and (10-11) decreases, while the distribution proportion of (10-10) increases.

Discussion

On the VD direction of the sample, as shown in Figure 6, the proportion of the (0001) crystal plane has significantly increased to 40%, compared to the 14.02% in the PDF card, while the proportion of the (10-10) crystal plane has decreased to 11.68%, a reduction of 20.19% from the 31.87% in the PDF card. From the above analysis, it can be understood that in the sintered block of composite powder prepared by in-situ reaction at 850°C, there is an orientation distribution of characteristic crystal planes. In the direction perpendicular to the pressure, WC grains rotate, causing the (0001) plane to become perpendicular to the pressure direction, thereby reducing the interfacial energy between WC grains. The sintered block of low-temperature in-situ reaction synthesis powder exhibits an orientation distribution characteristic of WC grain characteristic crystal planes, which is believed to be due to the formation of WC grains through secondary reactions during sintering, with atoms preferentially aligning along the (0001) plane and the rotation of WC grains under sintering pressure causing the (0001) plane to tend towards being perpendicular to the pressure direction.

When the temperature is raised to 900°C for in-situ reaction, the prepared composite powder is mainly WC with only a small amount of carbon-deficient phase. When the temperature is raised to 1000°C for in-situ reaction, pure WC-Co composite powder can be obtained. Since the crystal plane distribution of the grains in the powder is isotropic, the crystal plane distribution of WC grains does not change during the subsequent sintering densification process at 900°C and 1000°C, and they still exhibit a randomly distributed isotropic characteristic.

Wniosek

1) The nanoscale WC-Co composite powder prepared by low-temperature in-situ reduction carbonization reaction at 850°C can be sintered into cemented carbide block materials with a highly oriented distribution characteristic of WC grain crystal planes using SPS. The sintered blocks of in-situ reaction powder at 900°C and 1000°C maintain an isotropic distribution of WC grain characteristic crystal planes.

2) In the WC-Co cemented carbide with highly oriented characteristic crystal planes, the basal plane (0001) occupies the largest area fraction in the direction perpendicular to the sintering pressure, reaching 40.0%; the prism plane (10-10) occupies the largest area fraction in the direction parallel to the pressure, reaching 35.7%.

3) The phase purity of the composite powder generated by the in-situ reaction plays an important role in the crystal plane orientation of the sintered block. When the main phase of the composite powder is WC, the crystal plane distribution of the sintered block does not exhibit oriented characteristics. However, when the main phase of the composite powder is the carbon-deficient phase, the crystal plane of the sintered block presents an oriented distribution characteristic.

]]>

The Functions of the Different Parts of the Turning Tool

?Rake angle

The rake angle is the angle between the cutting face and the reference plane; it is an important indicator of how the cutting edge participates in the cutting process. The rake angle of the blade itself is usually a positive rake angle, and the shape of the cutting face can be a circular arc, chamfer, or flat surface. The size and sign (positive or negative) of the rake angle will affect the tool strength, cutting force, the tool’s finish machining capability, vibration tendencies, and chip formation. The rake angle has a significant impact on cutting force, chip evacuation, cutting heat, and tool life.

Impact of rake angle?size on cutting

1.A larger positive rake angleresults in a sharper cutting edge, but the strength of the cutting edge decreases.

2. A larger positive rake angle?reduces the cutting force; an excessively large negative rake angle?increases the cutting force.

?

Applications of different rake?angle sizes

K?t przy?o?enia

The relief angle has the function of avoiding the friction between the back tool face and the workpiece and making the tool tip cut into the workpiece freely.

Relief angle size and back tool face wear diagram

?Influence of relief angle size on turning tools

The relief angle is large, and the rear tool surface is worn less, but the strength of the tool tip is decreased, and the reverse is true when the relief angle is small.

Application of different size relief angle

Secondary rake angle

The secondary rake angle affects the mitigation of impact force, the size of the feed force component, the size of the back force component, and the chip thickness.

Impact of the size of the secondary rake angle on cutting

① When the feed rate is the same, a larger secondary rake angle increases the length of contact between the insert and the chip, resulting in a thinner chip thickness. This disperses the cutting force over a longer cutting edge, thereby improving the tool life.

② A larger secondary rake angle leads to an increase in the component force a’, which can cause bending when machining slender workpieces.

③ A larger secondary rake angle results in poorer chip handling performance.

④ A larger secondary rake angle leads to a thinner chip thickness and an increased chip width, making it difficult for the chip to break.

Secondary clearance angle

The angle designed to avoid interference between the machined surface and the tool (secondary cutting edge). It is usually between 5° and 15°.

Impact of the secondary clearance angle

① A smaller secondary clearance angle increases the strength of the cutting edge, but the tool tip is prone to heating.

② A smaller secondary clearance angle increases the back force, which can cause vibration during cutting.

③ For rough machining, a smaller secondary clearance angle is preferable; for finish machining, a larger secondary clearance angle is more suitable.

Inclination Angle

The inclination angle is the angle at which the cutting face is tilted. During heavy cutting, the tool tip at the starting point of the cut bears a significant impact force. To prevent the tool tip from being damaged by this force due to brittleness, an inclination angle for the cutting edge is necessary. In turning operations, it is generally set to 3°-5°;

① When the inclination angle is negative, the chips flow towards the workpiece.

When the inclination angle is positive, the chips are discharged in the opposite direction.

② When the inclination angle is negative, the cutting edge strength increases, but the cutting back force also increases, which can easily cause vibration.

Chamfering and blunting of the cutting edge

Chamfering and blunting of the cutting edge are treatments applied to the cutting edge to ensure its strength. Typically, this involves rounding or chamfering the cutting edge. The chamfer is a narrow band-like surface set along the cutting face or the back face. Usually, the grinding width is half the feed rate.

Influence of cutting edge grinding width on turning tools

① High cutting edge strength, reduced chance of chipping, and improved tool life.

② The wear on the flank face is likely to spread, resulting in a lower tool life. The width has no effect on the wear of the cutting face.

③ Increased cutting force, which can easily cause vibration.

Application of different tip widths

Tip radius

The tip radius is a key factor in turning operations. It has a significant impact on the strength of the tip and the roughness of the machined surface. The specific choice depends on the cutting depth and feed, and it will affect surface quality, chip breaking, and blade strength.

Influence of tip radius

Advantages of a larger tip radius:

① Improved surface roughness.

② Increased blade strength, less prone to chipping.

③ Reduced wear on the front and back of the tool.

Disadvantages of an excessively large tip radius:

① Increased cutting force, prone to vibration.

② Poor chip handling performance.

Application of different tool tip corner radius sizes

In addition, when selecting turning tools and parameters, it is necessary to consider factors such as the nature of the material being machined, the required precision, and the production volume.

]]>