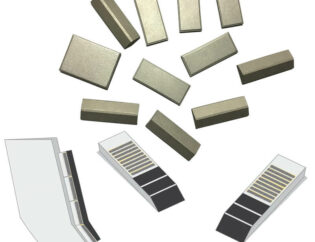

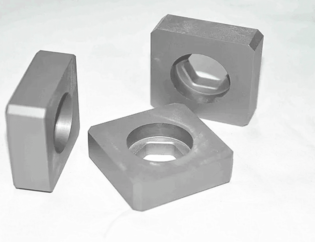

Tungsten Carbide Plate

Tungsten carbide plates are also named as tungsten carbide sheets, square plates, flat stock, and flat bars. They are made from tungsten carbide, which is harder than many materials in terms of corrosion resistance and wear resistance. So they can be used in woodworking, metal machining, and molding industry. All our carbide plates have been stress-relieving HIP sintered in order to gain resistance to corrosion, pitting and cracking commonly experienced during machining.

Sinterizzazione

ANCA.

Gli avanzati forni HIP controllati da computer vengono applicati per fornire più pressione durante il processo di sinterizzazione al fine di ottenere una struttura più densa.

Polvere

Eccellente.

Selezioniamo e controlliamo attentamente l'eccellente qualità delle nostre polveri grezze. La tecnologia di essiccazione a spruzzo di polvere garantisce l'uniformità della distribuzione delle particelle.

in lavorazione

In casa.

Offriamo ai clienti una vasta gamma di servizi di lavorazione in loco, tra cui rettifica senza centri, rettifica cilindrica CNC, rettifica interna CNC, elettroerosione a filo e incisione laser, ecc.

OEM Servizio Clienti

Possiamo sviluppare gradi secondo le vostre esigenze e realizzare la stessa forma del vostro disegno. Sono disponibili anche la marcatura laser e il pacchetto neutro per i vostri vantaggi.

Il voto

Grado | Densità | TSR | Durezza | Grain Size |

| MT15 | 14 | ≥3000 | ≥87.5 | 1.6 |

| MT650 | 13.9 | ≥3700 | ≥89.5 | 0.8 |

| MT20 | 14.2 | ≥3500 | ≥90 | 0.5~1.5 |

| YG6 | 14.8 | ≥1670 | ≥89.5 | 0.5~1.5 |

| YG6X | 14.8 | ≥1560 | ≥91 | 0.5~1.5 |

| YG8 | 14.7 | ≥1840 | ≥89 | 0.5~1.5 |

Tungsten Carbide is a hard but brittle ceramic material which generally contains 6% to 10% cobalt, forms a tough Cermet (Ceramic-Metal). We develop material for use in cutting tools and electrolysis such as electrodes in EDM. All these uses require tungsten carbide to have a structure consists of particle crystals of a few microns in size within a ductile metal matrix. The matrix structure can withstand the high compressive stresses imposed during cutting, as well as having good wear at any temperatures. On top of that, tungsten carbide has a high resistance to thermal shock, so it is tolerated to severe temperature fluctuation.

In a nutshell, qualified tungsten carbide plate should include these following properties,

- excellent red toughness

- high hardness

- good wear resistance

- high elastic?modulus

- high strength?

- good chemical stability and corrosion-proof

- Low impact toughness

- low expansion coefficient

- Nearly identical thermal conductivity?to?ferrous?metal.

?

Due to raw tungsten carbide material sourced from Germany and our stringent quality control, our tungsten carbide products competently engage in many industries, such as:

- Chemical

- Electric power

- Mechanical?machining

- Metallurgy

- Automobile industry