????? ????? ????? ?????? ??????? ?? ?????

?????? ????? ????? ????? ???????? ????? ??? ???? ???? ?? ??????? ????????? ???????? ????? ???????? ??????? ???????? ?? ???? ???? ???? ?? ??? ??????? ????????? ??????? ????? ???? ??? ???? ???.

??????

??? ?? ????.

??? ????? ????? HIP ???????? ???? ??? ?????? ???? ?????? ????????? ?????? ??? ???? ????? ????? ??????? ?? ??? ?????? ??? ???? ???? ?????.

?????

?????.

???? ??????? ?????? ?? ??????? HCStarck ? ?????? ???? ????? ?????? ????? ?? ?????? ????? ??????? ???????? ?????? ????? ?????.

????

???????

???? ??? ??? ????? ??????? ??? ??????? ??????? ??????? ??????? ????? ?? ???? ????? ?????? ???????? ????? ???? ?????? ?????? ????? ????????????.

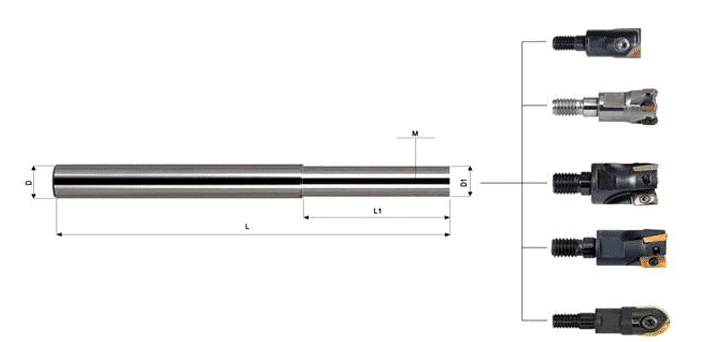

???? ??????

??????

OD

???? ?????

?????

12-100 ???

12

? 6

100

12-150-? 6

12

? 6

150

16-100- M8

16

? 8

100

16-150-M8

16

? 8

150

16-200-M8

16

? 8

200

16-250-M8

16

? 8

250

16-300-M8

16

? 8

300

20-100-? 10

20

? 10

100

20-150-? 10

20

? 10

150

20-200-M10

20

? 10

200

20-250-M10

20

? 10

250

20-300-M10

20

? 10

300

25-150-? 12

25

? 12

150

25-200-? 12

25

? 12

200

25-250-? 12

25

? 12

250

25-300-? 12

25

? 12

300

32-150-M16

32

? 16

150

32-200-M16

32

? 16

200

32-250-M16

32

? 16

250

32-300-M16

32

? 16

300

32-350-M16

32

? 16

350

32-400-M16

32

? 16

400

OEM ???? ?????

?????? ????? ??????? ????? ????????? ???? ??? ??? ????? ????? ??. ????? ????? ?????? ?????? ????? ?????? ???????.

????

????

? MT20.8

???? ISO

? K40-K50

WC + ????? ???

%

85

Co

%

15

??? ?????? WC

??????

0.8

?????

? /㎝3

13.95

?????

Hv30

1350

HRA

? 89.5

??? ???? ?????

N / ??2

3800

kpsi

? 551

??? ?????

Mpa.m?

17.5

????? ????

kpsi

79086

??? ?????

kpsi

957

Coolant Tungsten Carbide Rods with oil duct

Both carbide rod with straight coolant holes and helical coolant holes are supplied. Different grades are also available in stock. The internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities. It is widely used in deep-hole drills and thread end mills.

Type

D(mm)

d(mm)

Deviation of holes

position≤(mm)

L(mm)

?

Tol.

?

Tol.

???

??ol.

OD4.0×ID1.0×330

4.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD5.0×ID1.0×330

5.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD5.0×ID1.5×330

5.0

+0.2/+0.6

1.5

±0.15

0.2

330

0/+5

OD6.0×ID1.0×330

6.0

+0.2/+0.6

1.0

±0.15

0.2

330

0/+5

OD6.0×ID1.5×330

6.0

+0.2/+0.6

1.5

±0.15

0.2

330

0/+5

OD8.0×ID1.0×330

8.0

+0.2/+0.6

1.0

±0.15

0.25

330

0/+5

OD8.0×ID1.5×330

8.0

+0.2/+0.6

1.5

±0.15

0.25

330

0/+5

OD9.0×ID1.0×330

9.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD10.0×ID1.0×330

10.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD10.0×ID2.0×330

10.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD11.0×ID1.0×330

11.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD12.0×ID1.0×330

12.0

+0.3/+0.7

1.0

±0.15

0.25

330

0/+5

OD12.0×ID2.0×330

12.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD14.0×ID2.0×330

14.0

+0.3/+0.7

2.0

±0.2

0.25

330

0/+5

OD16.0×ID2.0×330

16.0

+0.4/+0.8

2.0

±0.2

0.25

330

0/+5

OD16.0×ID3.0×330

16.0

+0.4/+0.8

3.0

±0.25

0.25

330

0/+5

OD18.0×ID3.0×330

18.0

+0.4/+0.8

3.0

±0.25

0.3

330

0/+5

OD20.0×ID3.0×330

20.0

+0.4/+0.8

3.0

±0.25

0.3

330

0/+5

20.0≤Dia≤40.0 are available on request

20.0≤Dia≤40.0 are available on request

Type

D(mm)

TK(mm)

d(mm)

Deviation of holes position≤(mm)

L(mm)

?

Tol.(mm)

TK

Tol.

?

Tol.(mm)

???

Tol.(mm)

OD4.3×2ID0.8×1.8×330

4.3

0/+0.6

1.8

-0.4/0

0.8

±0.10

0.15

330

0/+10

OD5.3×2ID0.8×2.0×330

5.3

0/+0.6

2.0

-0.4/0

0.8

±0.10

0.20

330

0/+10

OD6.3×2ID1.0×3.0×330

6.3

0/+0.6

3.0

-0.5/0

1.0

±0.15

0.20

330

0/+10

OD7.3×2ID1.0×3.5×330

7.3

0/+0.6

3.5

-0.5/0

1.0

±0.15

0.20

330

0/+10

OD8.3×2ID1.0×4.0×330

8.3

0/+0.6

4.0

-0.6/0

1.0

±0.15

0.20

330

0/+10

OD9.3×2ID1.4×4.0×330

9.3

0/+0.6

4.0

-0.6/0

1.4

±0.15

0.20

330

0/+10

OD10.3×2ID1.4×5.0×330

10.3

0/+0.6

5.0

-0.6/0

1.4

±0.15

0.20

330

0/+10

OD11.3×2ID1.4×5.0×330

11.3

0/+0.6

5.0

-0.6/0

1.4

±0.15

0.28

330

0/+10

OD12.3×2ID1.75×6.0×330

12.3

0/+0.6

6.0

-0.6/0

1.75

±0.15

0.30

330

0/+10

OD13.3×2ID1.75×6.0×330

13.3

0/+0.6

6.0

-0.6/0

1.75

±0.15

0.34

330

0/+10

OD14.3×2ID1.75×7.0×330

14.3

0/+0.6

7.0

-0.6/0

1.75

±0.15

0.37

330

0/+10

OD15.3×2ID2.0×7.0×330

15.3

0/+0.6

7.0

-0.6/0

2.0

±0.20

0.37

330

0/+10

OD16.3×2ID2.0×8.0×330

16.3

0/+0.6

8.0

-0.6/0

2.0

±0.20

0.40

330

0/+10

OD17.3×2ID2.0×8.0×330

17.3

0/+0.8

8.0

-0.6/0

2.0

±0.20

0.47

330

0/+10

OD18.3×2ID2.0×9.0×330

18.3

0/+0.8

9.0

-0.6/0

2.0

±0.20

0.50

330

0/+10

OD19.3×2ID2.0×9.0×330

19.3

0/+0.8

9.0

-0.6/0

2.0

±0.20

0.50

330

0/+10

OD20.3×2ID2.5×10.0×330

20.3

0/+0.8

10.0

-0.8/0

2.5

±0.25

0.50

330

0/+10

Type

D(mm)

d(mm)

Tk

a

Pitch

?

?????

?

?????

TK

?????

P1

P2

P3

?????

OD3.3×2ID0.4×1.7×330

3.3

2.33

0.4

±0.10

1.7

0/-0.3

≤0.08

15.89

16.32

16.77

±0.23

OD4.3×2ID0.6×2.2×330

4.3

2.33

0.6

±0.15

2.2

0/-0.3

≤0.10

21.19

21.77

22.36

±0.31

OD5.3×2ID0.7×2.6×330

5.3

2.67

0.7

±0.15

2.6

0/-0.4

≤0.13

26.49

27.21

27.95

±0.38

OD6.3×2ID0.7×2.6×330

6.3

2.5

0.7

±0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD6.3×2ID1.0×2.6×330

6.3

2.5

1.0

±0.15

2.6

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD7.3×2ID1.0×3.7×330

7.3

2.5

1.0

±0.15

3.7

0/-0.4

≤0.15

37.09

38.09

39.13

±0.54

OD8.3×2ID1.0×4.0×330

8.3

2.5

1.0

±0.15

4.0

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD8.3×2ID1.0×3.5×330

8.3

2.5

1.0

±0.15

3.5

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD8.3×2ID0.6×2.8×330

8.3

2.5

0.6

±0.15

2.8

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD9.3×2ID1.4×4.8×330

9.3

2.5

1.4

±0.15

4.8

0/-0.6

≤0.20

47.68

48.97

50.32

±0.69

OD10.3×2ID1.4×4.8×330

10.3

2.75

1.4

±0.15

4.8

0/-0.6

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID0.7×2.6×330

10.3

2.75

0.7

±0.15

2.6

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID1.0×3.0×330

10.3

2.75

1.0

±0.15

3.0

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

OD10.3×2ID1.4×5.0×330

10.3

2.75

1.4

±0.15

5.0

0/-0.6

≤0.20

52.98

54.41

55.91

±0.77

OD11.3×2ID1.4×5.3×330

11.3

2.75

1.4

±0.15

5.3

0/-0.8

≤0.28

58.28

59.86

61.5

±0.85

OD12.3×2ID1.4×6.25×330

12.3

2.75

1.4

±0.15

6.25

0/-0.8

≤0.30

63.58

65.3

67.09

±0.92

OD12.3×2ID1.75×6.0×330

12.3

2.75

1.75

±0.20

6.0

0/-0.8

≤0.30

63.58

65.3

67.09

±0.92

OD13.3×2ID1.75×6.5×330

13.3

3.0

1.75

±0.20

6.5

0/-0.8

≤0.34

68.87

70.74

72.68

±1.00

OD14.3×2ID1.75×7.1×330

14.3

3.5

1.75

±0.20

7.1

0/-0.8

≤0.37

74.17

76.18

78.27

±1.08

OD14.3×2ID0.8×3.5×330

14.3

3.5

0.8

±0.15

3.5

0/-0.4

≤0.37

74.17

76.18

78.27

±1.08

OD14.3×2ID1.4×4.5×330

14.3

3.5

1.4

±0.15

4.5

0/-0.6

≤0.37

74.17

76.18

78.27

±1.08

OD15.3×2ID1.75×7.7×330

15.3

3.5

1.75

±0.20

7.7

0/-0.8

≤0.40

79.47

81.62

83.86

±1.15

OD16.3×2ID1.75×8.3×330

16.3

3.5

1.75

±0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

±1.23

OD16.3×2ID2.0×8.0×330

16.3

3.5

2.0

±0.20

8.0

0/-0.6

≤0.40

84.77

87.06

89.45

±1.23

OD17.3×2ID1.75×8.9×330

17.3

3.5

1.75

±0.20

8.9

0/-0.8

≤0.47

90.07

92.5

95.04

±1.31

OD18.3×2ID2.0×9.55×330

18.3

3.5

2.0

±0.25

9.55

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD18.3×2ID1.75×9.15×330

18.3

3.5

1.75

±0.20

9.15

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD19.3×2ID2.0×10×330

19.3

3.5

2.0

±0.25

10.0

0/-0.8

≤0.50

100.66

103.39

106.22

±1.46

OD20.3×2ID2.0×10.4×330

20.3

3.5

2.0

±0.25

10.4

0/-1

≤0.50

105.96

108.83

111.81

±1.54

Note: D<18.3, L>100, L Tolerance0~+7; L<100, L Tolerance0~+5.? D ≥ 18.3, L Tolerance+3~+10.

Note: D<18.3, L>100, L Tolerance0~+7, L<100, L Tolerance0~+5, D≥18.3, Length Tolerance+3~+10

Type

D(mm)

d(mm)

TK(mm)

a

Ptich

?

Tol.

?

Tol.

TK

Tol.

P 1

P 2

P 3

Tol.

OD6.3×2ID0.6×1.9×LC

6.3

2.5

0.6

±0.15

1.9

0/-0.4

≤0.15

18.20

18.85

19.52

±0.34

OD6.3×2ID0.5×2.2×LC

6.3

2.5

0.5

±0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

±0.42

OD8.3×2ID0.65×2.7×LC

8.3

2.5

0.65

±0.15

2.7

0/-0.6

≤0.15

28.91

29.95

31.04

±0.56

OD10.3×2ID0.8×3.5×LC

10.3

2.75

0.8

±0.15

3.5

0/-0.8

≤0.20

36.14

37.44

38.8

±0.70

OD12.3×2ID0.9×4.2×LC

12.3

2.75

0.9

±0.15

4.2

0/-0.8

≤0.30

43.37

44.93

46.55

±0.84

OD14.3×2ID1.0×4.7×LC

14.3

3.5

1.0

±0.20

4.7

0/-0.8

≤0.37

50.6

52.42

54.31

±0.98

OD16.3×2ID1.2×5.5×LC

16.3

3.5

1.2

±0.20

5.5

0/-0.8

≤0.40

57.82

59.9

62.07

±1.12

OD18.3×2ID1.4×6.3×LC

18.3

3.5

1.4

±0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

±1.26

OD20.3×2ID1.5×7.1×LC

20.3

3.5

1.5

±0.20

7.1

0/-1.0

≤0.50

72.28

74.88

77.59

±1.40

Note: D<18.3, L>100, L Tolerance0~+7; L<100, L Tolerance0~+5. D≥18.3, L Tolerance+3~+10.

Type

D(mm)

d(mm)

TK

a

Pitch

?

Tol.

?

Tol.

TK

Tol.

P 1

P 2

P 3

Tol.

OD6.3×3ID0.5×2.9×LB

6.3

2.5

0.5

±0.15

2.9

0/-0.4

≤0.15

31.79

32.65

33.54

±0.46

OD8.3×3ID0.7×4.0×LB

8.3

2.5

0.7

±0.15

4

0/-0.4

≤0.15

42.38

43.53

44.73

±0.62

OD9.3×3ID0.7×4.0×LB

9.3

2.5

0.85

±0.15

5.1

0/-0.5

≤0.20

47.68

48.97

50.32

±0.69

OD10.3×3ID0.85×5.1×LB

10.3

2.75

0.85

±0.15

5.1

0/-0.4

≤0.20

52.98

54.41

55.91

±0.77

BФ12.3×3Ф1.1×6.3×LB

12.3

2.75

1.1

±0.15

6.3

0/-0.6

≤0.30

63.58

65.3

67.09

±0.92

OD14.3×3ID1.4×7.3×LB

14.3

3.5

1.4

±0.20

7.3

0/-0.8

≤0.40

74.17

76.18

78.27

±1.08

OD15.3×3ID1.4×7.3×LB

15.3

3.5

1.4

±0.20

7.8

0/-0.8

≤0.40

79.47

81.62

83.86

±1.15

OD16.3×3ID1.6×8.3×LB

16.3

3.5

1.6

±0.20

8.3

0/-0.8

≤0.40

84.77

87.06

89.45

±1.23

OD18.3×3ID1.7×9.5×LB

18.3

3.5

1.7

±0.20

9.5

0/-0.8

≤0.50

95.36

97.95

100.63

±1.38

OD20.3×3ID1.9×10.2×LB

20.3

3.5

1.9

±0.25

10.2

0/-0.8

≤0.50

105.96

108.83

111.81

±1.54

Note:? D<18.3, L>100, L Tolerance0~+7, L<100, L Tolerance0~+5, D≥18.3, Length Tolerance+3~+10

Type

D(mm)

d(mm)

Tk

a

Pitch

?

Tol.

?

?????

TK

Tol.

P1

P2

P3

Tol.

OD6.3×3ID0.5×2.9×LB

6.3

2.5

0.5

±0.15

2.2

0/-0.4

≤0.15

21.68

22.46

23.28

±0.42

OD8.3×3ID0.7×4.0×LB

8.3

2.5

0.65

±0.15

2.7

0/-0.4

≤0.15

28.91

29.95

31.04

±0.56

OD10.3×3ID0.85×5.1×LB

10.3

2.75

0.8

±0.15

3.5

0/-0.4

≤0.20

36.14

37.44

38.8

±0.70

BФ12.3×3Ф1.1×6.3×LB

12.3

2.75

0.9

±0.15

4.2

0/-0.6

≤0.30

43.37

44.93

46.55

±0.84

OD14.3×3ID1.4×7.3×LB

14.3

3.5

1.0

±0.20

4.7

0/-0.6

≤0.37

50.60

52.42

54.31

±0.98

OD16.3×3ID1.6×8.3×LB

16.3

3.5

1.2

±0.20

5.5

0/-0.8

≤0.40

57.82

59.90

62.07

±1.12

OD18.3×3ID1.7×9.5×LB

18.3

3.5

1.4

±0.20

6.3

0/-0.8

≤0.50

65.05

67.39

69.83

±1.26

OD20.3×3ID1.9×10.2×LB

20.3

3.5

1.5

±0.20

7.1

0/-0.8

≤0.50

72.28

74.88

77.59

±1.40

??????

??? ?? ????.

??? ????? ????? HIP ???????? ???? ??? ?????? ???? ?????? ????????? ?????? ??? ???? ????? ????? ??????? ?? ??? ?????? ??? ???? ???? ?????.

?????

?????.

???? ??????? ?????? ?? ??????? HCStarck ? ?????? ???? ????? ?????? ????? ?? ?????? ????? ??????? ???????? ?????? ????? ?????.

Cooling

Internal.

The internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities. We supply not only straight coolant but also spiral coolant carbide rod.

OEM ???? ?????

?????? ????? ??????? ????? ????????? ???? ??? ??? ????? ????? ??. ????? ????? ?????? ?????? ????? ?????? ???????.

????

| ???? | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ???? ISO | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + ????? ??? | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| ??? ?????? WC | ?????? | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| ????? | ? / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| ????? | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| ??? ???? ????? | N / ??2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| ??? ????? | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| ????? ???? | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| ??? ????? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

???? | ??????? ?????????? |

MT09U? | ????? ???? ??????? ?? 9%Co ?????? ????? ????? ??????? ?????? ??????? ????? ???? ?????? ????? ? ????? ????????? ??? ??????? ?????? ?????????? ??????? ??????? ???????? ? HRC55-65 |

MT10S? | ????? ???? ??????? ?? 10%Co ?????? ????? ????? ??????? ???? ?????? ??? ????? ??? ????? ????????? ????? ?????? ????? ????? ?????? ????? HRC45 |

MT12S? | WC ?????? ??????? ?? 12%Co ????? ????? ??????? ???? ????? ?????? ?????? ??????? ??????? ????? ????????? ??? ??????? ??????? ????? ???????? ??????? ??? ?????? ?????? ?????????? ?????? ???? |

MT25S? | ????? ???? ??????? ?? 12%Co ????? ????? ?????? ??????? ???? ????? ????? ?????? ?????? ?????? ??????? ?? ????? ??? 45 ? 55 HRC ???????? ??????? ?????? ?????? ??????? |

MT06U? | WC ?????? ??? ???????? ?? 6% Co ?????? ????? ????? ????? ???? ????? ??????? ???? ???? ?????? ??????????? ? ????? ??????? ????? ?????? ? ????????? ? ??????? ? MDF |

MT20.8? | ????? ?????? ??? ???????? ?? 15%Co ??? ????? ?????? ????? ???? ?????? ????????? ?? ??????? ?????? ?? ??????? |

?????? ???????? ????? ???????? ??? ????????

??????

??? ?? ????.

??? ????? ????? HIP ???????? ???? ??? ?????? ???? ?????? ????????? ?????? ??? ???? ????? ????? ??????? ?? ??? ?????? ??? ???? ???? ?????.

?????

?????.

???? ??????? ?????? ?? ??????? HCStarck ? ?????? ???? ????? ?????? ????? ?? ?????? ????? ??????? ???????? ?????? ????? ?????.

??????

?????.

??? ??????? ???? ??? ??? ?????? ? ??? ?? ??? ????? ?????? ???????????? ?????? ???????? ????? ?????? ?????? ???? ??? ?? ??????? ?? ????? ????? ???????.

????? ??????? 330 ?? ? ???? ? ???? ????????

|

??? ??????? |

????? |

??????? ?? ????? |

??? ??????? |

????? |

??????? ?? ????? |

??? ??????? |

????? |

??????? ?? ????? |

|

0.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

9.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

19.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

|

1.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

10.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

20.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

|

1.2 |

+0.20/+0.45 |

.00.0 / + 10.0 |

10.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

20.5 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

1.6 |

+0.20/+0.45 |

.00.0 / + 10.0 |

11.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

21.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

1.8 |

+0.20/+0.45 |

.00.0 / + 10.0 |

11.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

22.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

2.3 |

+0.20/+0.45 |

.00.0 / + 10.0 |

12.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

23.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

2.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

12.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

24.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

3.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

13.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

25.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

3.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

13.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

26.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

4.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

14.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

27.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

4.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

14.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

28.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

5.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

15.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

29.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

5.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

15.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

30.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

6.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

16.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

31.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

6.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

16.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

32.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

7.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

17.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

33.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

7.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

17.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

34.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

8.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

18.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

35.0 |

+0.20/+0.80 |

.00.0 / + 10.0 |

|

8.5 |

+0.20/+0.45 |

.00.0 / + 10.0 |

18.5 |

+0.20/+0.60 |

.00.0 / + 10.0 |

|||

|

9.0 |

+0.20/+0.45 |

.00.0 / + 10.0 |

19.0 |

+0.20/+0.60 |

.00.0 / + 10.0 |

???? ?????? ????? 0.3 ?? ?????? ?????? 40 ??

OEM ???? ?????

?????? ????? ??????? ????? ????????? ???? ??? ??? ????? ????? ??. ????? ????? ?????? ?????? ????? ?????? ???????.

????

| ???? | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ???? ISO | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + ????? ??? | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| ??? ?????? WC | ?????? | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| ????? | ? / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| ????? | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| ??? ???? ????? | N / ??2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| ??? ????? | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| ????? ???? | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| ??? ????? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

???? | ??????? ?????????? |

MT09U? | ????? ???? ??????? ?? 9%Co ?????? ????? ????? ??????? ?????? ??????? ????? ???? ?????? ????? ? ????? ????????? ??? ??????? ?????? ?????????? ??????? ??????? ???????? ? HRC55-65 |

MT10S? | ????? ???? ??????? ?? 10%Co ?????? ????? ????? ??????? ???? ?????? ??? ????? ??? ????? ????????? ????? ?????? ????? ????? ?????? ????? HRC45 |

MT12S? | WC ?????? ??????? ?? 12%Co ????? ????? ??????? ???? ????? ?????? ?????? ??????? ??????? ????? ????????? ??? ??????? ??????? ????? ???????? ??????? ??? ?????? ?????? ?????????? ?????? ???? |

MT25S? | ????? ???? ??????? ?? 12%Co ????? ????? ?????? ??????? ???? ????? ????? ?????? ?????? ?????? ??????? ?? ????? ??? 45 ? 55 HRC ???????? ??????? ?????? ?????? ??????? |

MT06U? | WC ?????? ??? ???????? ?? 6% Co ?????? ????? ????? ????? ???? ????? ??????? ???? ???? ?????? ??????????? ? ????? ??????? ????? ?????? ? ????????? ? ??????? ? MDF |

MT20.8? | ????? ?????? ??? ???????? ?? 15%Co ??? ????? ?????? ????? ???? ?????? ????????? ?? ??????? ?????? ?? ??????? |

Cut-to-Length (CTL) Tungsten Carbide Rod, Ground, Polished, Chamfer one end

We have one of the largest and most complete lines of ground CTL carbide rods for cutting tool blanks in stock. Meetyou Carbide proudly announces that we have achieved the best cost-effectiveness for this kind of rods for cutting tool blanks. Because we use a unique method of pressing technology combined with the supreme quality powder from Germany H.C.Starck.

h6

Polished.

Our standard tolerance for the diameter is h6 polished. We can also provide h5 polished or other tolerance as per your requirement.

?????

Cut.

Both advanced wire cutting and diamond wheel cutting are applied to cut the carbide rod into the length you need.

One End

Chamfered

45 degree chamfered one end is provided for better looking and a smooth edge.

- Complete lines of ground cut to length carbide rod for cutting tool blanks

- Standard h6 ISO diameter tolerances in inch and metric lengths and diameters

- Special perform like male center, female center, ball nose, step reduction, and shaped points, etc are available according to your drawing

Standard Size ,Metric, Milimeter

|

Φ3.0 X 60 |

Φ8.0 X 50 |

Φ12.0 X 120 |

|

Φ4.0 X 40 |

Φ8.0 X 60 |

Φ13.0 X 100 |

|

Φ4.0 X 46 |

Φ8.0 X 63 |

Φ14.0 X 75 |

|

Φ4.0 X 50 |

Φ8.0 X 75 |

Φ14.0 X 80 |

|

Φ4.0 X 60 |

Φ8.0 X 90 |

Φ14.0 X 83 |

|

Φ4.0 X 75 |

Φ8.0 X 100 |

Φ14.0 X 100 |

|

Φ4.0 X 100 |

Φ10.0 X 50 |

Φ16.0 X 80 |

|

Φ5.0 X 50 |

Φ10.0 X 70 |

Φ16.0 X 90 |

|

Φ5.0 X 60 |

Φ10.0 X 72 |

Φ20.0 X 100 |

|

Φ5.0 X 100 |

Φ10.0 X 75 |

|

|

Φ6.0 X 40 |

Φ10.0 X 80 |

|

|

Φ6.0 X 50 |

Φ10.0 X 90 |

|

|

Φ6.0 X 58 |

Φ10.0 X 100 |

|

|

Φ6.0 X 60 |

Φ12.0 X 70 |

|

|

Φ6.0 X 67 |

Φ12.0 X 79 |

|

|

Φ6.0 X 75 |

Φ12.0 X 83 |

|

|

Φ6.0 X 100 |

Φ12.0 X 100 |

OEM ???? ?????

?????? ????? ??????? ????? ????????? ???? ??? ??? ????? ????? ??. ????? ????? ?????? ?????? ????? ?????? ???????.

????

| ???? | ? | MT09U | MT10S | MT12S | MT25S | MT06U | MT20.8 |

| ???? ISO | ? | K10-K20 | K20-K40 | K20-K40 | K20-K40 | K05-K10 | K40-K50 |

| WC + ????? ??? | % | 91 | 90 | 88 | 88 | 93.5 | 85 |

| Co | % | 9 | 10 | 12 | 12 | 6.5 | 15 |

| ??? ?????? WC | ?????? | 0.4 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| ????? | ? / ㎝3 | 14.5 | 14.42 | 14.12 | 14.1 | 14.85 | 13.95 |

| ????? | Hv30 | 1890 | 1600 | 1580 | 1750 | 1890 | 1350 |

| HRA | ? | 93.5 | 91.5 | 91.2 | 92.5 | 93.5 | 89.5 |

| ??? ???? ????? | N / ??2 | 3800 | 4100 | 4200 | 4400 | 3700 | 3800 |

| kpsi | ? | 590 | 609 | 638 | 540 | 551 | 551 |

| ??? ????? | Mpa.m? | 10.2 | 14.2 | 14.7 | 13.5 | 10.1 | 17.5 |

| ????? ???? | kpsi | 86780 | 85360 | 80860 | 80000 | 91000 | 79086 |

| ??? ????? | kpsi | 1145 | 1015 | 1010 | 1109 | 1156 | 957 |

???? | ??????? ?????????? |

MT09U? | ????? ???? ??????? ?? 9%Co ?????? ????? ????? ??????? ?????? ??????? ????? ???? ?????? ????? ? ????? ????????? ??? ??????? ?????? ?????????? ??????? ??????? ???????? ? HRC55-65 |

MT10S? | ????? ???? ??????? ?? 10%Co ?????? ????? ????? ??????? ???? ?????? ??? ????? ??? ????? ????????? ????? ?????? ????? ????? ?????? ????? HRC45 |

MT12S? | WC ?????? ??????? ?? 12%Co ????? ????? ??????? ???? ????? ?????? ?????? ??????? ??????? ????? ????????? ??? ??????? ??????? ????? ???????? ??????? ??? ?????? ?????? ?????????? ?????? ???? |

MT25S? | ????? ???? ??????? ?? 12%Co ????? ????? ?????? ??????? ???? ????? ????? ?????? ?????? ?????? ??????? ?? ????? ??? 45 ? 55 HRC ???????? ??????? ?????? ?????? ??????? |

MT06U? | WC ?????? ??? ???????? ?? 6% Co ?????? ????? ????? ????? ???? ????? ??????? ???? ???? ?????? ??????????? ? ????? ??????? ????? ?????? ? ????????? ? ??????? ? MDF |

MT20.8? | ????? ?????? ??? ???????? ?? 15%Co ??? ????? ?????? ????? ???? ?????? ????????? ?? ??????? ?????? ?? ??????? |